TPU Drying Temperature: The Ultimate Guide

TPU (Thermoplastic Polyurethane) filament is prized for its flexibility, durability, and abrasion resistance — but it’s also highly sensitive to moisture. In this ultimate guide, we'll dive into the optimal drying temperatures for TPU.

Key Points

For optimal results, dry Snapmaker TPU filaments at 65-70°C for 8 hours and store at indoor temperature with humidity below 25%.

TPU90 and TPU-Foam require 70°C, while standard TPU95 needs 65°C. High Flow TPU95 also needs 70°C. Proper drying eliminates moisture-related print defects like bubbling, stringing, and poor layer adhesion.

Want to master TPU moisture management like a professional? Read on for the science, techniques, and best practices that will elevate your printing results.

Why TPU Drying Temperature Matters

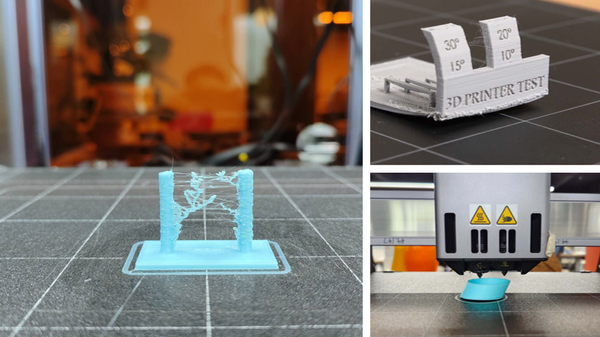

TPU filament is highly hygroscopic, readily absorbing moisture from the air. When this moisture-laden filament is heated in your printer's hot end, the water rapidly converts to steam, causing numerous printing issues:

- Bubbling, hissing sounds during extrusion

- Poor layer adhesion between print layers

- Excessive stringing and oozing

- Rough or inconsistent surface finish

- Reduced part strength and flexibility

- Potential nozzle clogging

You may be interested in TPU Filament 3D Printing Guide: Temperature, Speed, and More.

What Is the Best Temperature to Dry TPU?

The sweet spot for drying most TPU filaments lies between 40°C and 65°C, though specific formulations like Snapmaker's may benefit from temperatures up to 70°C.

Lower Temperatures (40-50°C):

- Safer for filament structure

- Minimizes risk of the filament sticking together

- Requires significantly longer drying times

Higher Temperatures (55-70°C):

- Accelerates moisture removal

- More time-efficient

- Must stay below the material's softening point

The relationship between temperature and drying time is inverse—higher temperatures mean faster moisture removal, but also increased risk of filament damage if temperatures are too high.

The Science Behind Temperature Selection

TPU has a glass transition temperature (Tg) that affects how water molecules move through the material. Heating above this temperature (but well below melting point) significantly increases molecular mobility, allowing moisture to escape more efficiently. Heating TPU too high can cause:

- Filament layers on the spool to fuse together

- Thermal degradation of the polymer chains

- Reduction in mechanical properties

Snapmaker-Specific Drying Parameters

Shop Snapmaker Premium 3D Printer Filament.

Drying Methods for TPU Filament

Several approaches exist for drying TPU filament, in order of effectiveness:

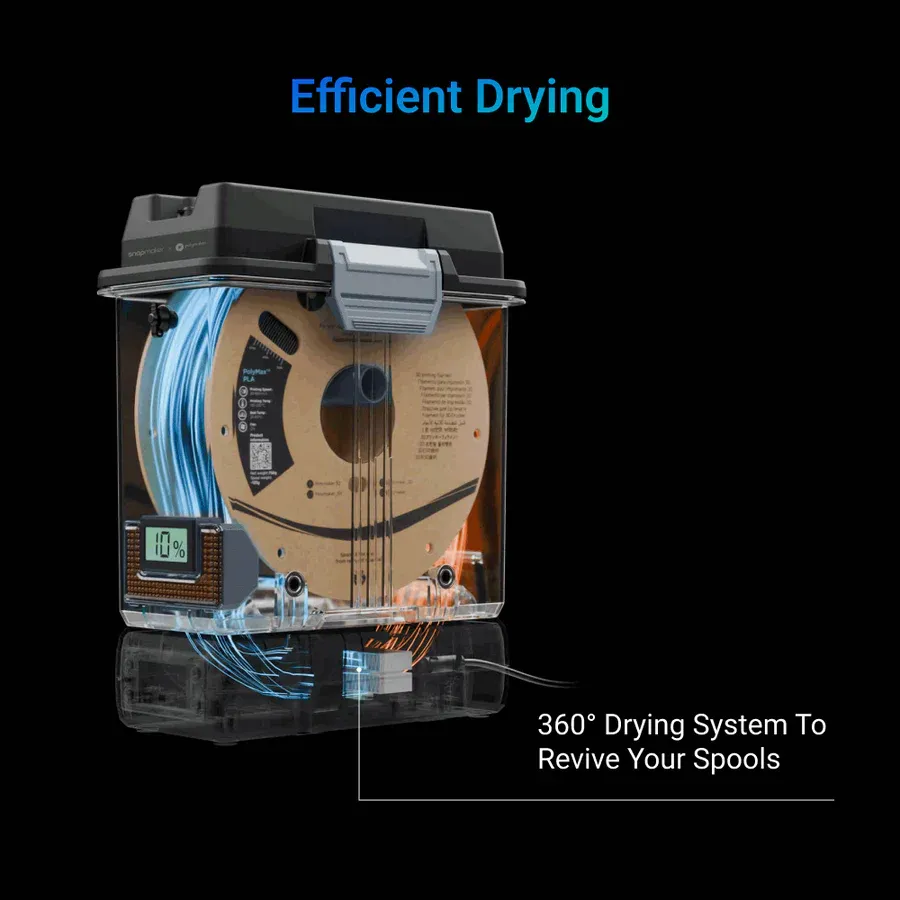

- Dedicated Filament Dryers: Purpose-built devices with precise temperature control, such as the SnapDryer — a combined filament dryer and storage solution.

- Food Dehydrators: Cost-effective alternative with reasonable temperature regulation

- Conventional Ovens: Use with caution and external temperature monitoring

- Heated Bed + Enclosure: Less effective but accessible option for emergency drying

Beyond drying to the correct temperature:

- Store dried filament in airtight containers with desiccant

- Maintain humidity below 25% for optimal storage

- Consider printing from a heated dry box for critical applications

- Re-dry when necessary based on visual and performance cues

How to Tell When Drying TPU is Necessary

Signs your TPU needs drying:

- Crackling sounds during extrusion

- Bubbles in extruded filament lines

- Excessive stringing compared to when new

- Rough surface finish on prints

- Layers that separate easily

- Condensation inside packaging

Common Considerations

- Always check manufacturer recommendations for specific TPU formulations

- Drying is not instantaneous – proper time is as important as temperature

- Ambient humidity affects both drying effectiveness and storage requirements

- Even properly packaged new filament may require drying in humid environments