PETG vs. PLA: Which 3D Printing Filament is Right for Your Project?

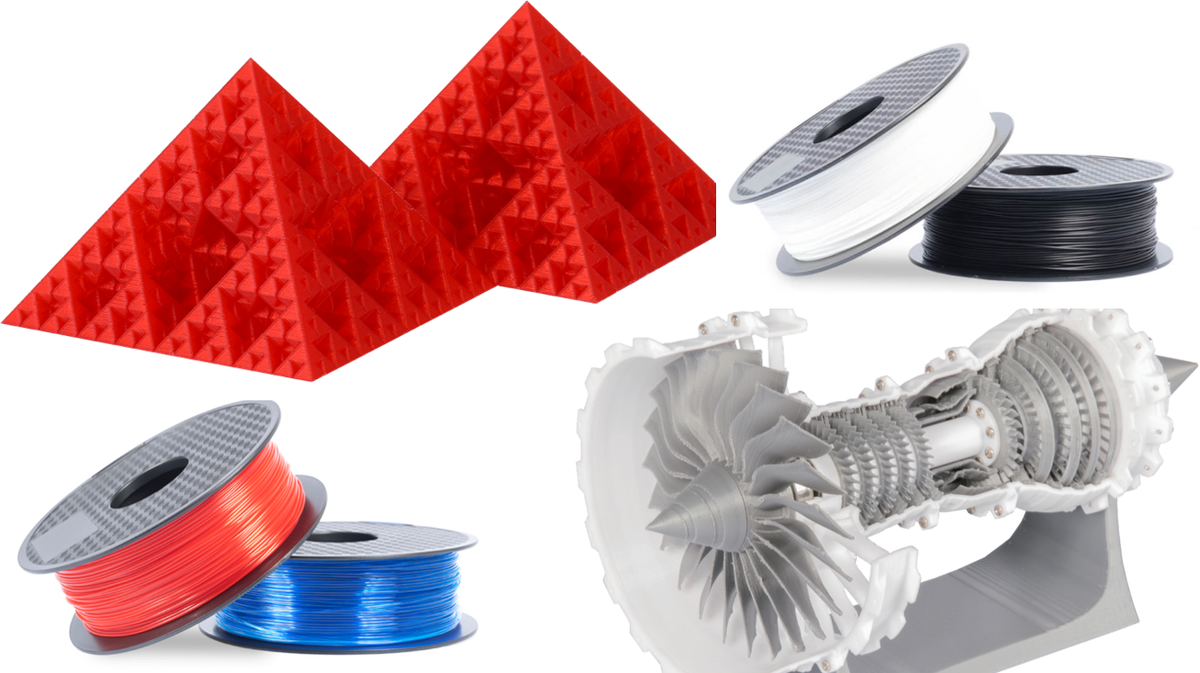

You’ve just downloaded the perfect model. You’re ready to slice it, but then you hit the drop-down menu for "Material" and hesitate. Should you load the reliable, easy-to-print PLA, or is it time to switch to that spool of PETG you bought months ago but haven't dared to open yet?

It’s a common frustration. You want your print to be strong, but you don't want to spend hours fighting with stringing or clogged nozzles. The truth is, both materials are excellent, but they serve completely different masters. PLA is the gold standard for aesthetics and consistency, while PETG is the workhorse of functionality.

This guide will cut through the technical noise and help you decide exactly which filament type to use for your specific project, ensuring your print doesn't just look good—it lasts.

The Short Answer: When to Choose Which

If you have the slicer open right now and just need to know what to click, start here.

Choose PLA If...

- You are a beginner or value reliability: Basic PLA is the most forgiving material. It rarely warps, sticks easily to the bed (25–60°C), and delivers consistent results without needing an enclosure. It’s the perfect starting point for those looking for easy 3D printing ideas.

- Visual quality is your top priority: For display models, intricate figurines, or architectural mock-ups, Basic PLA offers the best detail resolution. If you need to hide layer lines specifically, variants like Matte PLA offer a refined finish right off the printer.

- You need high stiffness: Surprisingly, Basic PLA is stiffer than PETG. It holds its shape rigidly under load (up to ~46.6 MPa tensile strength), making it great for static displays.

Choose PETG If...

- The part needs to flex: You are making mechanical parts, brackets, or snap-fit components. PETG is ductile; it will bend slightly under pressure rather than snapping suddenly like PLA.

- It’s going outside: You need durability against UV light and weather.

- Heat resistance matters: The part will be used in a hot environment (up to ~80°C), such as inside a dishwasher, a parked car, or near a stepper motor.

- You have a moisture-controlled setup: You are prepared to dry your filament, as PETG absorbs moisture quickly which causes stringing.

PETG vs. PLA: The Core Differences Explained

To make the best choice, it helps to understand why these materials behave differently. It’s not just about "stronger" or "weaker"—it’s about how the plastic reacts to stress and your printer’s environment.

Ease of Printing: Stability vs. Stringing

Basic PLA is widely considered the king of consistency. It melts at a moderate temperature (190–230°C) and cools rapidly, allowing for sharp corners and complex overhangs. Because it shrinks very little as it cools, you rarely have to deal with warping or prints detaching from the bed.

PETG requires higher temperatures (typically 230–240°C) and a hotter build plate (70–80°C). It is naturally "sticky," which provides excellent layer adhesion but often leads to stringing—those wispy strands that mar the print surface.

Tip: PETG stringing is often caused by wet filament. If you see cobwebs on your print, dry your PETG at 65°C for roughly 4 hours before adjusting your retraction settings.

Strength and Durability: Stiffness vs. Ductility

The "strength" debate often confuses users because it depends on how you break the part.

- PLA is stiff but brittle. According to official data, Basic PLA has a high Tensile Strength (46.6 MPa) and a high stiffness (Young's Modulus of ~2636 MPa). It resists pulling very well. However, if you overload it, it snaps catastrophically.

- PETG is ductile. With a lower stiffness (Young's Modulus ~1472 MPa) and higher elongation (6.8%), PETG is softer. Under stress, it yields. This makes it superior for parts that need to absorb impact or vibration without shattering.

For a deeper look at material properties, check out our guide on the strongest 3D printer filaments.

Heat Resistance: The "Hot Car" Test

This is often the deciding factor. Basic PLA has a Glass Transition Temperature of around 61°C. If you leave a PLA print in a hot car during summer, it will soften and warp. PETG, with a Glass Transition Temperature of ~81°C, can withstand significantly higher heat, making it safer for functional parts in garages or machinery.

Applications and Use Cases for PETG and PLA

Let’s apply these specs to real-world scenarios.

Outdoor Projects and Planters

Winner: PETG

There’s a myth that PLA will "rot away" in your garden, but it actually needs industrial composting conditions to biodegrade. PLA can warp in heat, causing planters to droop in the sun. PETG, on the other hand, can withstand higher temperatures (~80°C) and resists UV rays better, making it a more reliable choice for outdoor use.

Cosplay and Display Models

Winner: Basic PLA

For cosplay, you want a surface that is easy to finish. PETG is difficult to sand—it tends to "gum up" sandpaper. Basic PLA sands cleanly, making it the ideal base for sanding and smoothing before painting your prints.

Mechanical Parts and Brackets

Winner: PETG (or PLA+)

If you are designing a clamp, a gear, or a buckle, you need the material to flex. PETG’s ductility prevents it from cracking under the strain of assembly. While PLA is stronger statically, its brittleness makes it a liability for snap-fits.

Food Safety

Winner: Caution Required

A common question is whether you can use these materials for kitchenware. While raw PETG is chemically similar to water bottles, the 3D printing process leaves micro-gaps that harbor bacteria. If you intend to use 3D prints with food, always follow a specific food-safe 3D printing guide.

The Wild Card: What is PLA+? (And Other Variants)

You might see spools labeled PLA+, Pro PLA, or High-Speed PLA and feel overwhelmed. Is "PLA+" a completely new material? Do you need to learn new settings?

Here is the secret: Think of them as "Flavors" of the same family.

PLA+ (often branded as "Tough PLA" or products like SnapSpeed PLA) is simply Basic PLA that has been enhanced with additives. These additives usually make the plastic less brittle (tougher) or allow it to flow faster through the nozzle.

If you are a beginner, you don't need to stress about the differences. They all print almost exactly the same way.

- The "Vanilla" Choice: Basic PLA. This is the best option for 90% of your projects because it is the standard material that is reliable, cost-effective, and easy to work with. If you’re unsure, start with this option.

- The "Performance" Choice: PLA+ / SnapSpeed PLA. This choice is ideal for functional parts where you need speed and added toughness, as it bridges the gap between PLA and PETG. It is less likely to snap than Basic PLA while still being easy to print.

- The "Artistic" Choice: Matte PLA. Matte PLA is perfect for statues and decorative items because it has a textured finish that conceals layer lines, giving your print an appearance similar to ceramic or clay.

Dive Deep: PLA Matte vs. Basic: Guide to Selecting Your Perfect Finish

Don't let the labels scare you. If you can print Basic PLA, you can print PLA+ or Matte PLA without changing much (if anything) in your settings.

Summary Comparison Table

Here is how the official specifications compare. Note that while these figures are based on Snapmaker filaments, they serve as a good baseline for most high-quality materials on the market.

[Data Source: Snapmaker Official]

Final Verdict: Building Your Filament Library

You don't need to choose one "forever filament." Most makers keep both on hand.

- Stock up on Basic PLA for 90% of your printing. It is cost-effective, easy to use, and perfect for drafting, toys, and household items.

- Keep a spool of PETG for specific functional needs—like that replacement vacuum part or a bracket for your bike. To ensure it stays ready to print, make sure you know how to store your filament to prevent moisture absorption.

By understanding the strengths of each, you stop guessing and start printing with confidence.

FAQ on PETG vs. PLA

Is PETG stronger than Basic PLA?

A: It depends on the definition of strength. Basic PLA actually has higher tensile strength (it resists pulling better), but it is brittle. PETG has higher impact strength, meaning it can absorb shocks and drops better without shattering.

Are Snapmaker filaments compatible with other 3D printers?

A: Yes. Snapmaker Basic PLA, Matte PLA, and SnapSpeed PLA are compatible with most FDM 3D printers that use 1.75 mm filament. Just ensure you use the recommended temperature settings.

Is printing with these materials safe?

A: Both PLA and PETG are generally considered safe for home use, but they do emit micro-particles. It is always good practice to ensure good ventilation. For more details, read about toxic odors in 3D printing.

Does PLA+ solve the heat resistance issue of PLA?

A: Generally, no. While PLA+ (and variants like SnapSpeed PLA) is tougher and less brittle than Basic PLA, it usually shares the same low glass transition temperature (~60°C). For high-heat applications, PETG is still the better choice.