How to Calculate Your 3D Printing Costs

It’s a common story: you calculate a print's cost at $2.00, while a professional service quotes the same part at $45. Why the huge difference? For hobbyists, the cost of 3D printing can feel like a mystery. Is it just the price of filament? The short answer is that it's a little more than that, but still easy to figure out.

This guide will break it all down. We'll give you simple formulas to understand exactly what your prints cost, helping you budget for your hobby and maybe even price a few prints for friends with confidence.

The Quick Answer: Your 3D Print Cost Master Formula

For the user who wants an immediate answer, here’s the formula we’re going to build. This is all you need for a solid estimate of your real-world costs.

Your Total Hobby Cost = (Filament Cost + Waste Cost) + Electricity Cost + Nozzle Wear Cost

We'll explain each part below.

Step 1: Calculating Filament Cost (The Obvious Part)

This is the cost everyone thinks of first. It’s simple to calculate, but there are a few hidden parts to consider that can make a big difference.

Your Model & Support Material

First, the basics. After you slice your model in software like Cura or PrusaSlicer, it tells you exactly how much filament the final part and any support structures will use, usually in grams (g).

The formula is straightforward:

Filament Cost = (Weight of Print in grams / 1000) × Cost of Spool

For example, if your print uses 50g of a 1kg (1000g) spool that cost you $22, your calculation is (50 / 1000) * $22 = $1.10. Easy.

More Than Just the Model: Accounting for Waste Material

Here’s something most people forget: your printer uses extra plastic to make sure your print is successful. This includes the skirt it draws to prime the nozzle and the brim it adds for bed adhesion. This is usually a small amount.

The biggest source of waste comes from multi-color printing. To get a clean switch from black to white, the printer has to push out a lot of plastic into a "purge tower" or "purge block." This waste isn't in your final part, but you still pay for it.

Purge Waste Calculator: See How Much Purge Waste is Costing You

It's tough to guess how much waste a multi-color print will make. We built a simple calculator to help you see the potential cost, so you can decide if that multi-color print is worth it.

How Much Filament Are You Paying to Purge?

As you can see, the costs can add up quickly. It's why efficient tool changer systems are key to keeping these costs down on colorful prints.

Step 2: Calculating Electricity Cost (The Small, but Steady Part)

While not a huge expense for one print, this adds up over hundreds of hours of printing. Your slicer gives you the estimated print time, which is all you need.

The Simple Electricity Formula

The formula looks like this:

Energy Cost = Print Time (hours) × (Printer Wattage / 1000) × Your Cost per kWh

You can find your cost per kWh on your monthly utility bill. Most desktop 3D printers run between 50W and 150W. A good estimate is to use 100W if you're unsure.

So, for a 10-hour print on a 100W printer with electricity at $0.17/kWh, it would be: 10 hours × (100W / 1000) × $0.17 = $0.17.

A Detailed Cost Breakdown: How Much Electricity Does a 3D Printer Use?

For Aspiring Sellers: Adding Professional Costs

If you’re thinking about selling your prints, you need to account for a few more real-world costs to make sure you're actually profitable. Think of this as moving from a hobby budget to a business plan.

Machine Depreciation: Paying Yourself Back for Your Printer

Your printer is a machine that wears out over time, just like a car. Each print should contribute a tiny amount to its eventual repair or replacement. This is called depreciation, and it helps you determine if buying a new machine is worth it.

Depreciation per Hour = Printer Purchase Cost / Total Expected Lifespan in Hours

A common lifespan estimate for a well-maintained printer is around 5,000 hours. So, if your printer costs $800, its depreciation cost is $800 / 5000 hours = $0.16 per hour.

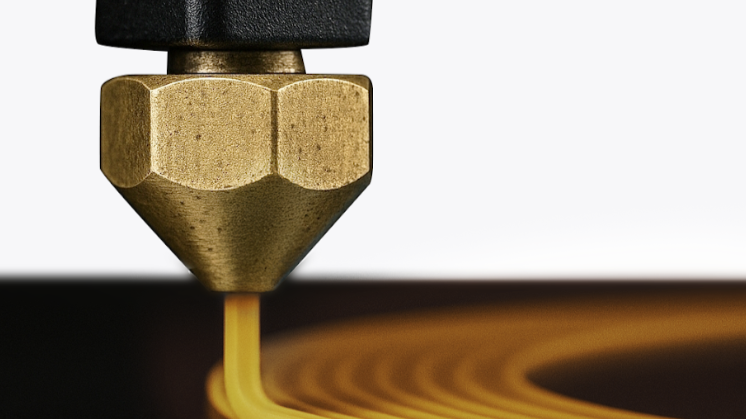

A Smarter Way to Calculate Nozzle Wear

Here’s a more advanced tip. A nozzle wears out from hot plastic being pushed through it, not from moving through the air. So, calculating its wear based on the amount of filament it processes is far more accurate.

Nozzle Wear Cost = Total Filament Volume (cm³) × (Nozzle Price / Nozzle's Volumetric Lifespan)

Check your slicer for the filament volume. A standard brass nozzle might last for 15,000 cm³ of PLA. For a $1 nozzle, that's a tiny cost per print, but accurately tracking it is what separates a hobby from a business.

Valuing Your Time: From File Prep to Finishing

Your time is valuable. When pricing a job for someone else, you must include your labor. Break it down into two parts:

- Pre-Press: The time you spend downloading, preparing, orienting, and slicing the file.

- Post-Processing: This is often the real time-sink. It's the work you do after the print is done: removing supports, sanding, cleaning, and curing.

Planning for Failure: The Cost of Imperfection

No one has a 100% success rate. If 1 in every 10 of your prints fail, you need to build that cost into the price of the 9 successful prints.

Risk-Adjusted Cost = Base Production Cost / (1 - Your Failure Rate)

For example, if your base cost is $10 and you have a 10% failure rate (0.10), your true cost is $10 / (1 - 0.10) = $11.11. This buffer ensures that one failed print doesn't erase your profit.

FAQ on 3D Printing Costs

Q: How to calculate filament cost?

A: To calculate filament cost, multiply the weight of your print in grams (from your slicer) by the price per gram of your filament spool. The formula is: (Weight of Print in grams / Weight of Spool in grams) × Cost of Spool.

Q: How much does 1 g of filament cost?

A: The cost per gram depends on the spool's price. To find it, divide the total cost of the spool by its weight in grams. For a standard 1kg (1000g) spool that costs $22, the price is $22 / 1000g = $0.022, or 2.2 cents per gram.

Q: How much does it cost to run a 3D printer for 24 hours?

A: It depends on your printer's wattage and your electricity rate. A typical 100W printer running for 24 hours at an electricity rate of $0.17 per kWh would cost approximately $0.61. The formula is: (100W / 1000) × 24 hours × $0.17/k