Laser Fume Safety: Your Guide to an Effective Laser Cutter Exhaust System

Laser engraving and cutting technology enables creators to transform materials like wood, acrylic, and leather into intricate designs and functional parts. For hobbyists and small businesses using devices like the Snapmaker Artisan, managing fumes and particles is essential for safe operation.

Many users ask: can a laser cutter be used indoors safely? Yes, with proper fume management. This guide covers laser emissions, exhaust system components, and practical advice for setup and maintenance to ensure workspace air quality

Understanding Laser-Generated Emissions

When a laser beam interacts with material, it causes rapid heating and vaporization, resulting in a plume that contains various airborne substances. The composition of this plume depends heavily on the material being processed. Key components include:

- Airborne Particulates: These are solid particles suspended in the air, ranging in size from coarse (visible dust) to very fine (sub-micron). Many common materials, such as wood and acrylics (like PMMA), are known to produce significant quantities of these particles during laser processing. The size of these particles dictates how deeply they can be inhaled.

- Volatile Organic Compounds (VOCs): These are carbon-containing chemicals that become gases at room temperature. The thermal decomposition of many materials, including plastics (e.g., ABS, though not recommended for lasering due to hazardous byproducts like hydrogen cyanide), adhesives in composite woods (like plywood, which can release formaldehyde), and certain treated leathers, can release a variety of VOCs. Some VOCs can contribute to odor and may have other health implications depending on their nature and concentration.

- Other Gaseous Byproducts: Depending on the material, other gases can be formed. For instance, cutting materials containing chlorine (like PVC, which is strongly discouraged for laser cutting) can release hydrogen chloride, a corrosive gas.

While the specific health effects of chronic exposure to low levels of mixed laser-generated emissions in a workshop setting can be complex to quantify, established industrial hygiene principles recommend minimizing exposure to airborne contaminants wherever feasible. Effective fume management helps control these emissions at the source, contributing to better indoor air quality and a more comfortable working environment.

Components of an Effective Laser Cutter Exhaust System

A well-designed laser cutter exhaust system is crucial for capturing and managing these emissions. It typically consists of several key components working in synergy:

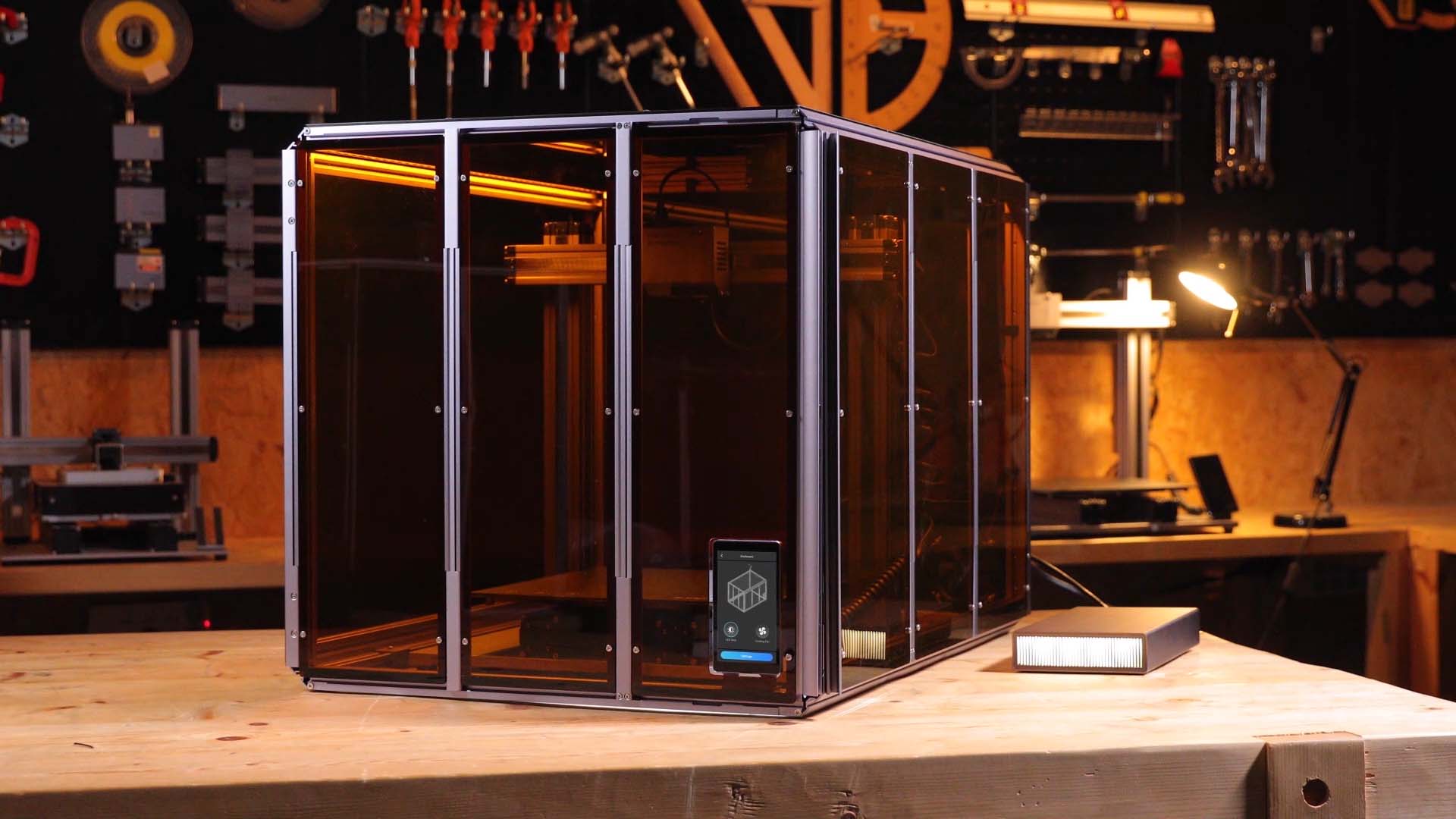

The Enclosure: Primary Containment

A properly designed enclosure around the laser processing area (such as those available for Snapmaker machines) serves as the first barrier, helping to contain the emissions plume near the point of generation. This makes subsequent extraction more efficient.

Ducting & Connections: Directing Airflow

Ducting provides a sealed pathway for transporting the captured air from the enclosure to either an air purification unit or an external vent. Important considerations for your laser cutter exhaust include:

- Smooth Interior Walls: To reduce turbulence and particulate settling.

- Appropriate Diameter: To match the airflow requirements of your fan or laser fume extractor.

- Airtight Seals: To prevent leakage of contaminated air back into the workspace.

Air Purification or Venting: Removing Contaminants

This is where the decision of "Do You Need a Laser Fume Extractor?" becomes central.

Laser Fume Extractors / Air Purifiers

These devices are designed to draw air from the enclosure and pass it through a series of filters. Key elements to look for include:

- Multi-Stage Filtration: Typically, this involves a pre-filter for larger particles, a HEPA (High-Efficiency Particulate Air) filter for fine particulates, and an activated carbon filter for adsorbing many VOCs and odors. The effectiveness and lifespan of these laser fume extractor filters are important.

- Sufficient Airflow (CFM - Cubic Feet per Minute): The unit must be capable of creating adequate negative pressure within the enclosure and processing the volume of air effectively. This may vary based on enclosure size and the intensity of laser operations (e.g., a diode laser fume extractor will be matched to typical diode laser setups).

- For Snapmaker users, the Snapmaker Air Purifier is an example of an integrated system with multi-stage filtration and airflow designed for compatibility with machine enclosures.

Outdoor Venting

This involves ducting the exhaust directly outside. While seemingly simple, considerations include local environmental regulations, potential impact on neighbors, and ensuring make-up air for the workshop.

Fan System: The Driving Force

The fan, whether integrated into a laser fume extractor or as a standalone unit in a venting system, provides the motive force to draw air through the entire laser cutter exhaust system. Its capacity must be matched to the resistance of the filters and ductwork.

Recirculation vs. Exhaust: Operational Choice

Recirculating systems (using a laser fume extractor with robust filtration) return cleaned air to the room, offering flexibility in workshop layout and avoiding the need for external wall penetrations. Exhaust systems vent air outside. The choice depends on feasibility, type of contaminants, and local conditions. High-quality recirculating systems can effectively address the question "Can a laser cutter be used indoors safely?" by significantly reducing indoor air contaminants.

Setup, Maintenance, and Troubleshooting Your Fume Extraction System

Setup and Installation

- Positioning: Create shortest, straightest duct run possible to maximize airflow

- Assembly: Follow manufacturer instructions carefully

- Connections: Ensure all joints are airtight with proper clamps and sealing tape

- Testing: Conduct test cuts to check for smoke leaks or odors

- Snapmaker Users: Connect the Air Purifier hose to the enclosure port and power on

Maintenance

- Filters: Monitor and replace according to manufacturer guidelines or when noticing reduced performance

- Ductwork: Check regularly for damage, blockages, and seal integrity

- Cleaning: Wipe down enclosure interior and extractor exterior periodically

Troubleshooting

- Check filter saturation and installation when experiencing odors/smoke

- Inspect system for leaks if fumes are escaping

- Replace clogged filters when airflow is reduced

- Clear obstructed ductwork to improve performance

- Check fan operation if ventilation seems weak

PPE Considerations

- A proper exhaust system is your primary protection

- Use NIOSH-approved respirators when working with irritating materials

- Wear appropriate mask when changing saturated filters

- Consider additional protection if you have individual sensitivities

For persistent issues, consult manufacturer documentation or contact support.

Breathe Easier and Create Safely with Proper Laser Fume Management

Laser technology offers incredible creative freedom. By implementing and diligently maintaining an effective laser cutter exhaust system, often incorporating a quality laser fume extractor, you ensure a workspace that is not only more pleasant but also proactively manages airborne emissions. Understanding the principles of fume generation and control empowers you to make informed decisions for your workshop, allowing you to focus on innovation and craftsmanship.