3D Printer Buying Guide: How to Choose Your First 3D Printer

This 3D printer buying guide covers the key factors to consider when choosing a 3D printer for beginners and recommends a versatile 3D printer for all skill levels.

3D printers have become incredible tools for crafting, prototyping, and creating unique designs. But with so many options available, choosing the best 3D printer for a beginner can feel overwhelming.

This guide is designed to change that. We'll walk you through a simple, step-by-step decision-making process to help you find the perfect first 3D printer that aligns with your needs and creative ambitions.

Step 1: Start with the "Why": What Do You Want to Make?

Before looking at any specs or features, the most important question to ask yourself is: "What kinds of objects do I want to create?" Your answer will point you toward the right type of printing technology.

Generally, creative projects fall into two main categories:

- Path A: For Detailed Miniatures, Jewelry, and Organic Shapes? If your goal is to print objects with incredibly fine details and smooth, flawless surfaces, you are likely looking for a Resin (SLA) printer.

- Path B: For Functional Parts, Prototypes, Gadgets, and Toys? If you plan to make larger, more durable objects like custom brackets, desk organizers, or tabletop gaming terrain, then a Filament (FDM) printer is the right choice, especially when you consider how strong 3D printed parts can be.

Step 2: Choose Your Technology: FDM vs. Resin (SLA)

FDM and Resin are the two primary types of desktop 3D printing. They work in fundamentally different ways and are suited for different tasks. For a detailed comparison, you can read our complete guide on FDM vs. SLA.

Quick Comparison: FDM vs. Resin

FDM (Fused Deposition Modeling)

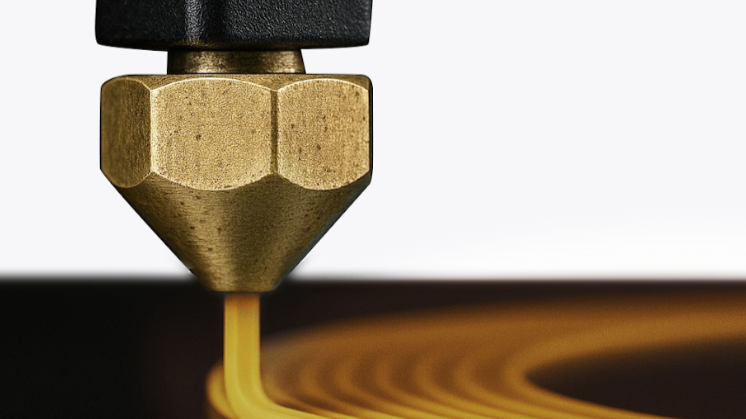

Think of an FDM printer as a smart, robotic hot glue gun. It takes a spool of solid plastic 3D printer filament, melts it, and draws an object layer by layer on a build platform until the part is complete.

- Pros: FDM printers are incredibly versatile, affordable, and work with a wide variety of strong, durable plastics (like PLA and ABS). They typically offer much larger build volumes, allowing you to create bigger parts.

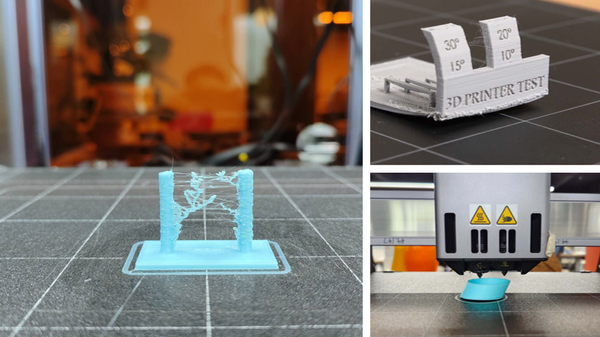

- Cons: The layer-by-layer process can leave visible lines on the final print, making it less ideal for projects requiring hyper-smooth surfaces.

Resin (SLA - Stereolithography)

Resin printing works by using a UV laser to cure and solidify a liquid photopolymer resin layer by layer in a vat.

- Pros: SLA can produce objects with breathtaking detail and an incredibly smooth surface finish, far beyond what is possible with FDM. This makes it the undisputed champion for things like detailed miniatures, jewelry prototypes, and dental models.

- Cons: The process can be messy, as it involves handling liquid resin and requires a multi-step washing and curing process after printing. The materials are also generally more expensive and less durable than FDM filaments.

What About Other Technologies like SLS?

You may also hear about other technologies like SLS (Selective Laser Sintering), which uses a laser to fuse powdered material. While incredibly powerful for producing strong, functional parts, SLS printers are currently industrial-grade machines far outside the scope and budget of a first-time buyer.

For this reason, as a beginner choosing your first 3D printer, your decision will be between the two primary and accessible desktop technologies: FDM and Resin.

Step 3: Key Features Every Beginner Should Look For

Once you've chosen between FDM and Resin, look for these features to ensure a smooth and enjoyable experience.

- Automatic Bed Leveling: This is the single most important feature for a beginner. A perfectly level print bed is critical for a successful first layer, and manual leveling can be a frustrating process. Automatic bed leveling automates this, saving you time and preventing many common first layer problems.

- Build Volume: Consider the size of the objects you want to create. While a larger build volume is always nice, a standard size (around 200 x 200 x 200 mm) is more than enough for most beginner projects.

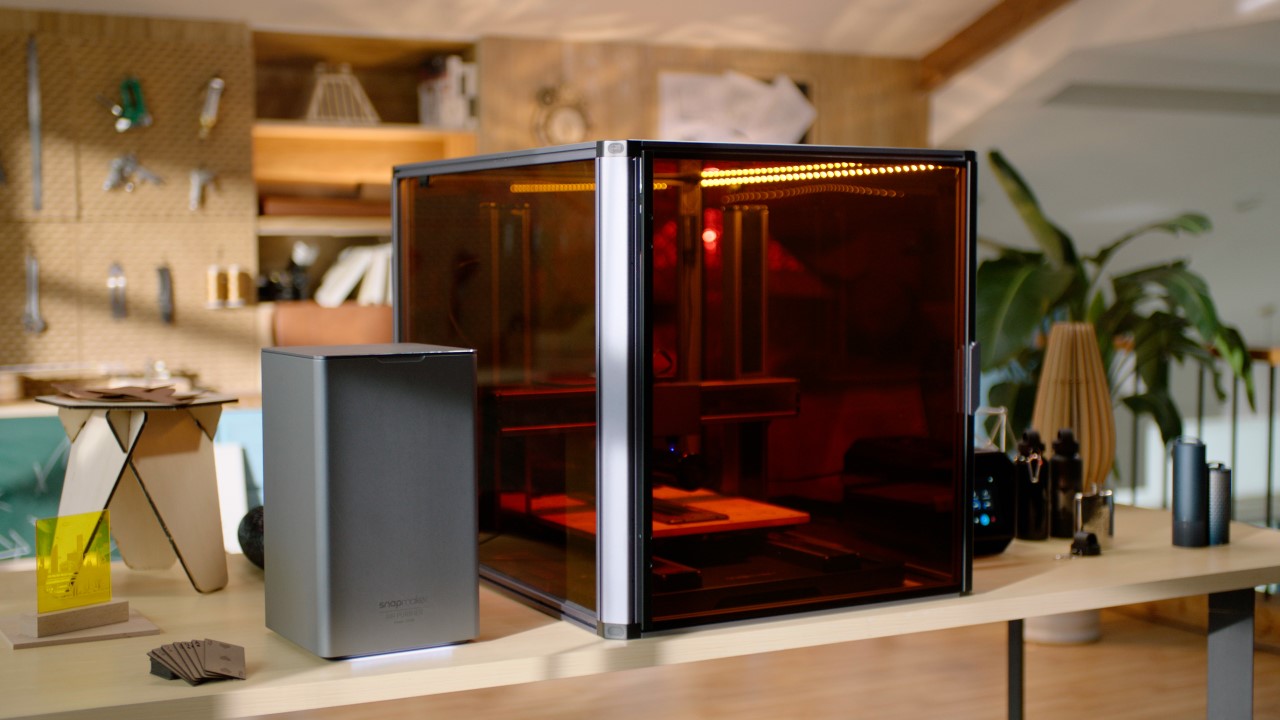

- An Enclosure: An enclosure is a housing that surrounds the printer. It helps maintain a stable temperature, which improves print quality with materials like ABS. More importantly, it provides a safety barrier, containing any fumes and keeping curious pets or hands away from hot and moving parts.

- Software and Community: A 3D printer is only as good as its software. Look for a machine that comes with an intuitive, user-friendly slicer that can translate your designs into G-code. A strong online community is also a huge asset for getting help, finding tips, and sharing your creations.

Step 4: So, Which Snapmaker Printer is Right for You?

Choosing a first printer is also about choosing an ecosystem you can grow with.

- For the All-in-One Creator & Explorer: Snapmaker Artisan. If you're a creative person who is excited by 3D printing but also interested in other making methods, the Artisan is the ultimate starting point. As a 3D printer, it features a dual-extrusion system and an expansive 400 x 400 x 400 mm work area, giving you the freedom to print large-scale projects in one piece. But its capabilities don't stop there. It's a complete 3-in-1 machine that also includes a powerful 40W Laser Engraver & Cutter and a robust 200W CNC Carver & Cutter. Its modular design allows you to quickly swap toolheads, transforming the machine from a 3D printer to a laser cutter or CNC carver in minutes. The platform is built to accommodate an ecosystem of addons and upgrades, such as the Rotary Module, ensuring your creative capabilities will continue to expand over time. This makes it a complete digital fabrication workshop in a single machine, allowing you to grow your skills across multiple disciplines.

- For the Ambitious, Future-Focused Maker: Snapmaker U1. If you know you want to be on the cutting edge of 3D printing from day one, the U1 is the choice. It's engineered for high-speed production, reaching print speeds of 300 mm/s with a blistering acceleration of 20,000 mm/s². As an advanced Tool Changer, it also provides clean, multi-color printing without the significant waste and hassle common to other systems.

Frequently Asked Questions

Is 3D printing hard for a beginner to learn? The learning curve is easier than ever. With modern features like automatic bed leveling, user-friendly software, and strong online communities, most beginners can get their first successful print within hours of unboxing their machine.

How much does a good beginner 3D printer cost? Entry-level printers can be found for a few hundred dollars, while more advanced, feature-rich machines can range from $1,000 to $2,500. Consider the long-term value; a 3-in-1 machine like the Artisan is worth it as it can save you from buying two other machines down the road.

Should I get an FDM or Resin printer for miniatures? For the absolute highest level of detail for display-quality miniatures, Resin is the winner. For durable miniatures that will be handled frequently for tabletop gaming, FDM is an excellent and more affordable choice.