How does Snapmaker J1 achieve both high-efficiency and high-quality IDEX 3D printing?

Retain the 0.1 mm layer height at the speed of 350 mm/s.

Hi Makers,

As we all know, 3D printing is still fundamentally slow. This attribute manifests itself more evidently in FDM technology. Depending on the complexity and dimension of models, and the user’s need for accuracy, some kinds of prints take hours or even days to finish. The underlying logic is a trade-off between quality and time.

Snapmaker J1 is a brand-new product that successfully secures quality and speed simultaneously for its users. Compared to major IDEX 3D printers in the market, one of the shining features of J1 is high-speed printing. It is usually not easy for an IDEX 3D printer to speed up. On the one hand, two independent extruders mean more weight, which increases the inertia. On the other hand, the X-axis has to carry more weight while moving two print heads. Under this circumstance, achieving accurate movements is more challenging. Given this structural challenge, we still effectively improved the printing speed performance of J1, retaining the 0.1 mm layer height at the speed of 350 mm/s.

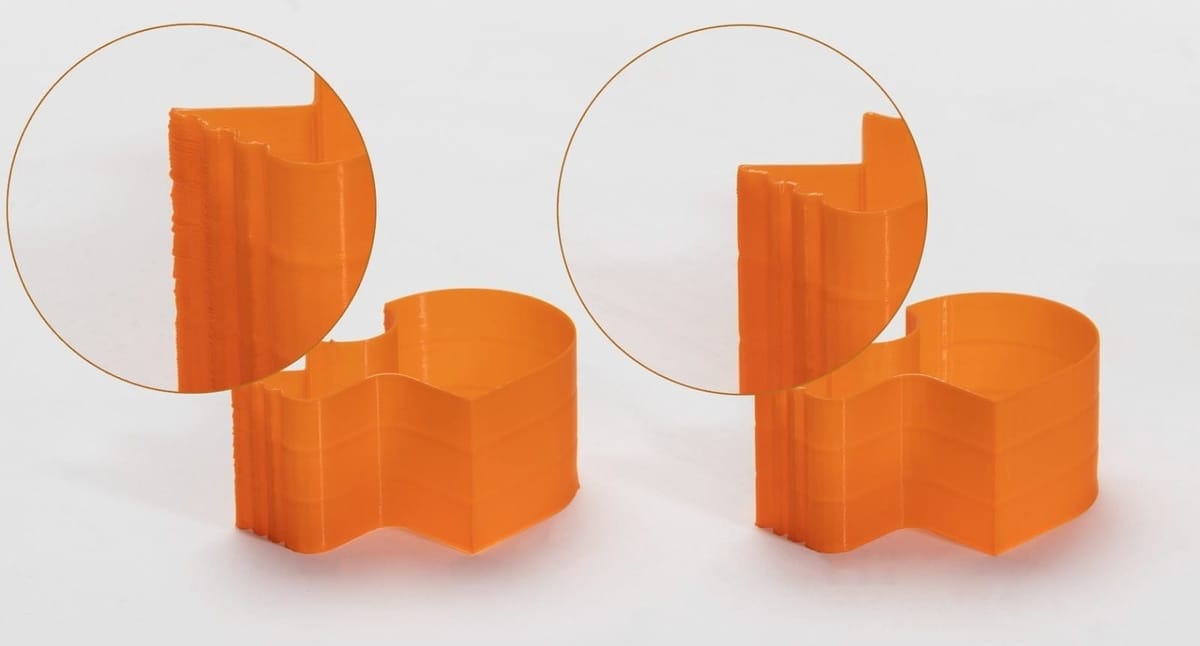

It’s made possible by four firmware- and software-based solutions. The first is vibration compensation, also known as Input Shaping. High-speed movement is prone to excessive or residual vibration, particularly at the end of a movement, leaving unwanted ringing or ghosting effects on prints, thus compromising quality. Input shaping is a preemptive approach to counter vibration. Based on specific resonant frequencies, the input shaping technique yields the command signal sent out several waves one after another. The amplitude of multiple waves will be ultimately superimposed on each other, and thus, the vibration can be perfectly canceled out.

Below is a screenshot documenting the degree of vibration when input shaping is on and off in J1. As you can see, the uneven part of the line shows free vibration, which occurs when the print head once changes the direction of its movement.

3D-printing sharp corners at a fast speed will easily disrupt print quality. Therefore, second, we optimize cornering speed by analyzing moving directions ahead of time, which can improve print quality at corners.

Third, the print head running in zigzags over short distances often accelerates and brakes in alternation. And this process could be pretty jerky and noisy when the entire machine shakes with it. Thus, we also adjust the maximum possible print speed when the print head zigzagging at high frequencies.

The above improvements were inspired by the open-source firmware Klipper. The great news is that in addition to J1, vibration compensation will also be realized in Snapmaker Artisan and Snapmaker 2.0. Please stay tuned for future firmware updates.

Fourth, we introduce a nonstop switching mechanism into IDEX printing, bringing the advantages of IDEX into full play. This mechanism applies to the scenario where the two print heads work alternatively, as in bicolor printing. Usually, only when one extruder finishes printing and then parks aside will the other extruder start heating up from the standby temperature to the initial printing temperature and then be switched back and resume printing.

Now, with our improvements in software and firmware, the non-operating extruder will preheat to the initial printing temperature while waiting and head to the goal position right after the operating extruder leaves for the resting position. In this way, the two extruders switch to each other seamlessly, providing a nonstop experience for J1’s users. Watch the video below and see how it works!

https://videopress.com/v/QisgoctA?resizeToParent=true&cover=true&preloadContent=metadata&useAverageColor=true Note: The Shark model in use was kindly provided by the model designer @mcgybeer.

Apart from software- and firmware-based improvements, the hardware components of J1 also lay a solid foundation for faster print speed and better print results. J1’s body comprises an upper frame, a base made by one-piece die casting, and four aluminum alloy bars. J1 is so rigid and reliable with minimal wobble and deformation possible. The industrial-grade linear rails are made by CNC grinding at the micron level, ensuring smooth and steady movements.

We briefly explained how J1 achieves both high-efficiency and high-quality IDEX printing in this blog. What do you think? Leave your thoughts below!