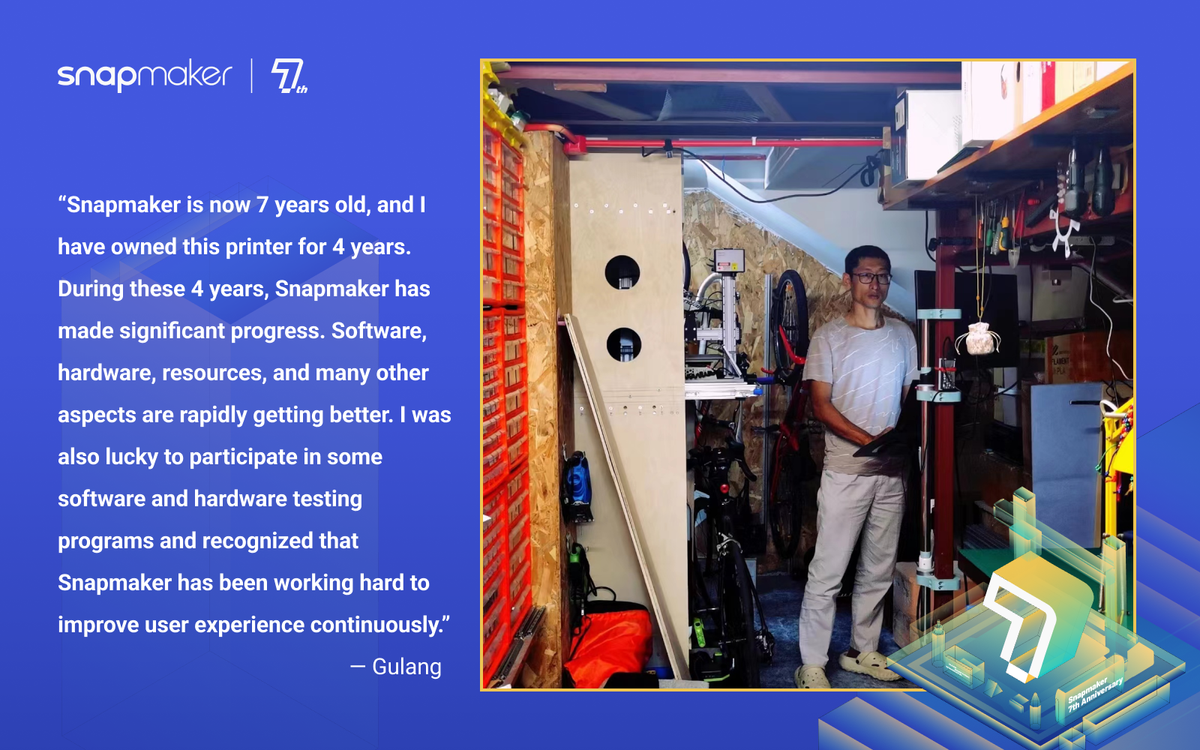

Snapmaker 7th Anniversary Column | Letter from Gulang

"Snapmaker is now 7 years old, and I have owned this printer for 4 years. During these 4 years, Snapmaker has made significant progress. Software, hardware, resources, and many other aspects are rapidly getting better. I was also lucky to participate in some software and hardware testing programs an

Hi Makers,

Gulang has been a Snapmaker 2.0 user for 4 years. He is an electrical engineer who is keen on designing and making interesting stuff by himself. Recently, he also beta-tested the Snapmaker 2.0 Quick Swap Kit and provided valuable feedback to Snapmaker.

When did you become a Snapmaker user?

I saw Snapmaker's second-generation machine on the crowdfunding platform Kickstarter in 2019 and placed an order. After a long wait, I finally received an email informing me that the printer had been shipped and they were assembled as soon as they were received. At that time, I was completely ignorant of 3D printing and didn't even know the principle. I only knew that it is done layer by layer. After the machine was installed, all three functions were tested. I didn't choose to use the official model samples, but instead downloaded the models myself from the internet, one Batman and one Iron Man. It took me a long time to slice them, so in the end I scaled down the Iron Man model. These two models are still on my desk in my office (Batman'shead has already fallen off).

Why did you choose Snapmaker?

I knew that the initial crowdfunding was very successful. Lots of users supported it. The appearance also looks good, and there are three functions that can meet my needs quite well.

What is the most memorable project you have ever done with Snapmaker 3D printer?

When I bought a Wuling Miniev car years ago, the original gear knob position was too low, making it inconvenient to operate. So I gradually learned to make models and create samples, and printed a total of 2KG of materials before completing the final product. This can be counted as my first work.

Since becoming a Snapmaker user, what have you gained in your maker journey?

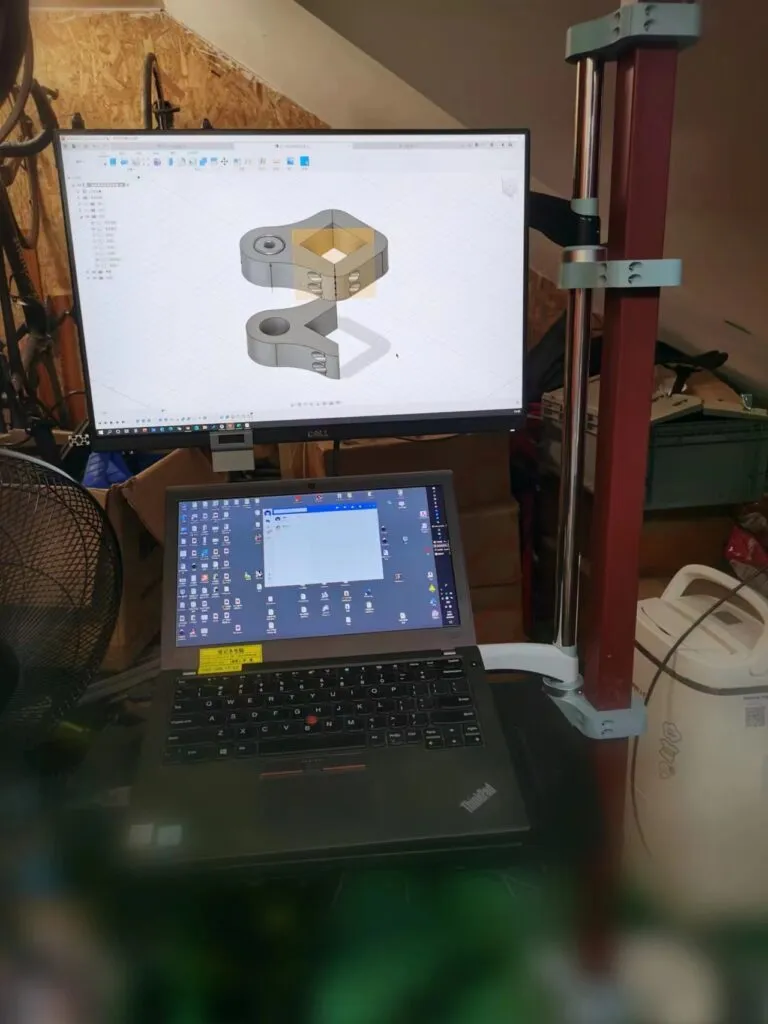

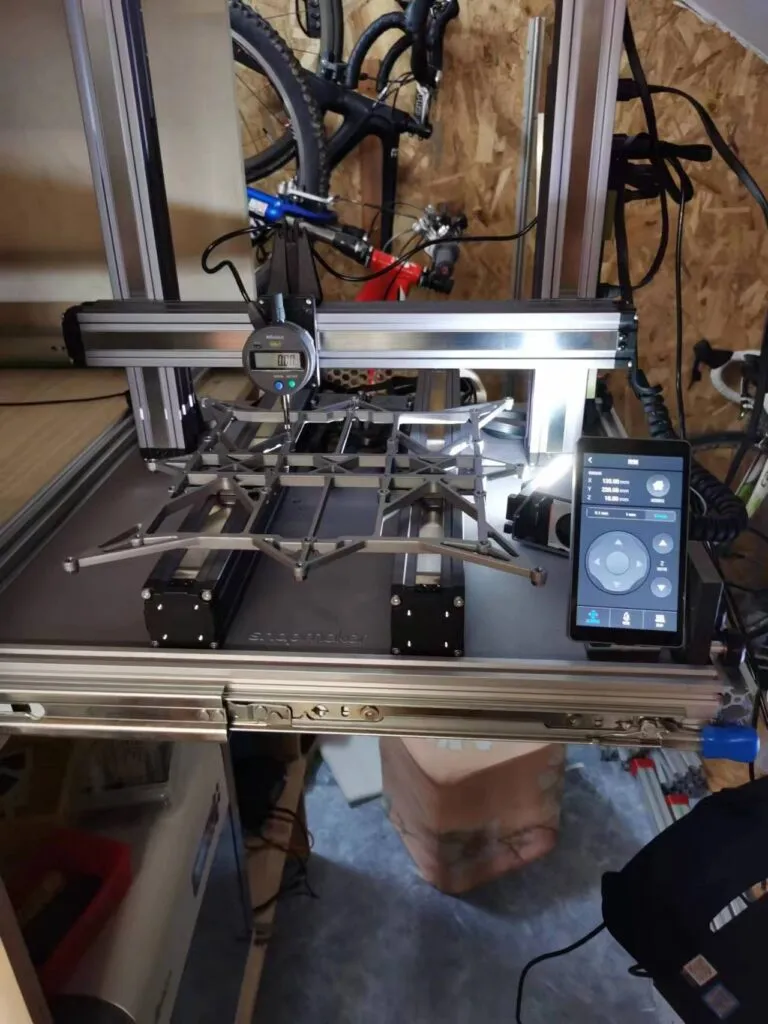

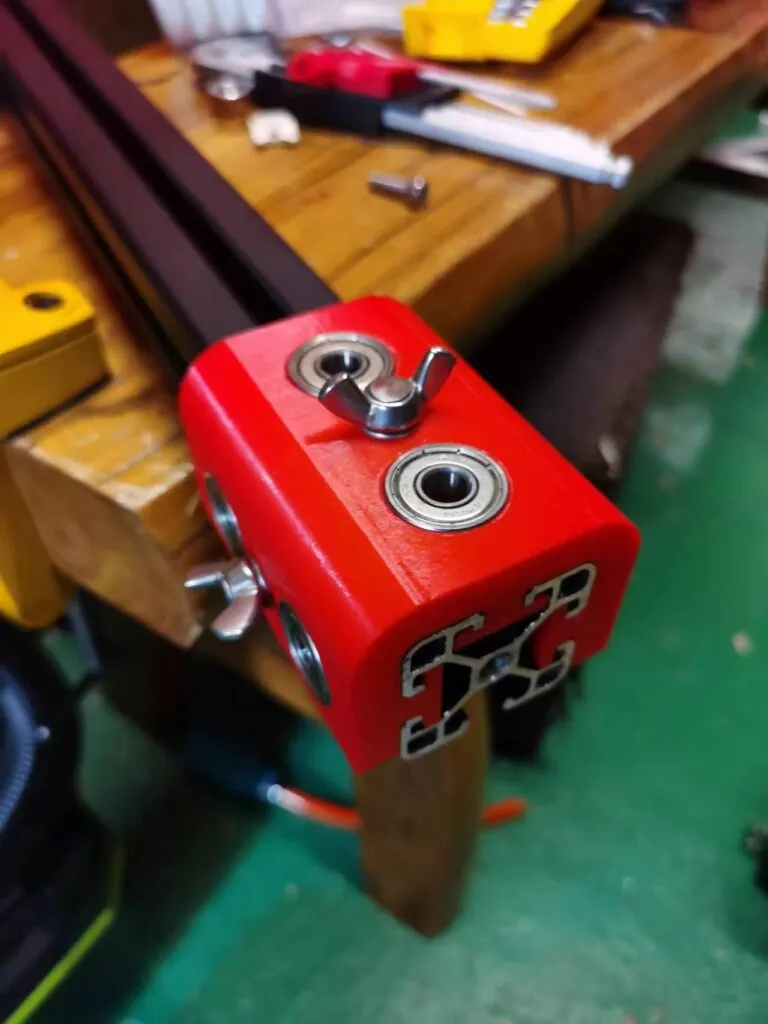

I made more friends via the user community, learned knowledge that I didn't know before, and I started making more progress. I realized that there are so many things 3D printing can do, and there is so much knowledge behind it. Gradually, more and more 3D printed models have been integrated into various things I usually design and produce: office equipment, car accessories, household accessories, equipment maintenance tools, woodworking tools, tool racks, and so on. What was originally impossible or difficult to implement has become simple and convenient. The dream is becoming true. In order to better utilize the performance of the machine, I will need to tweak it. Therefore, I have specially designed a rack and cabinet for easy maintenance and adjustment. At the same time, I have conducted tests, data analysis, and other tests on various aspects of the printer to ensure that the machine operates in good working condition.

From your perspective, what progress has Snapmaker made over these years?

Snapmaker is now 7 years old, and I have owned this printer for 4 years. During these 4 years, Snapmaker has made significant progress. Software, hardware, resources, and many other aspects are rapidly getting better. I was also lucky to participate in some software and hardware testing programs and recognized that Snapmaker has been working hard to improve user experience continuously. Nowadays, the printing speed is more than twice as fast as when I first bought it, and the print quality is also greatly improved. There are also more and more functions, accessories, and new models, which are getting better and better.

What do you want to say to the Snapmaker team?

I would like to say to the Snapmaker team, thank you for designing this interesting product. Your spirit of continuous effort is worth learning. While constantly launching new products, please also keep improving the experience of the previous models. I wish you all the best.