Snapmaker 2.0: Enclosures prototypes and pilot production #2

Snapmaker 2.0 enclosures are coming! See the latest prototypes & learn about the design improvements. Plus: pilot production update.

This September has been crazy as always. We have been testing and iterating the design of enclosures for Snapmaker 2.0 and following up with everything of pilot production #2 (small scale) and whole machine testing.

You will love the new enclosures

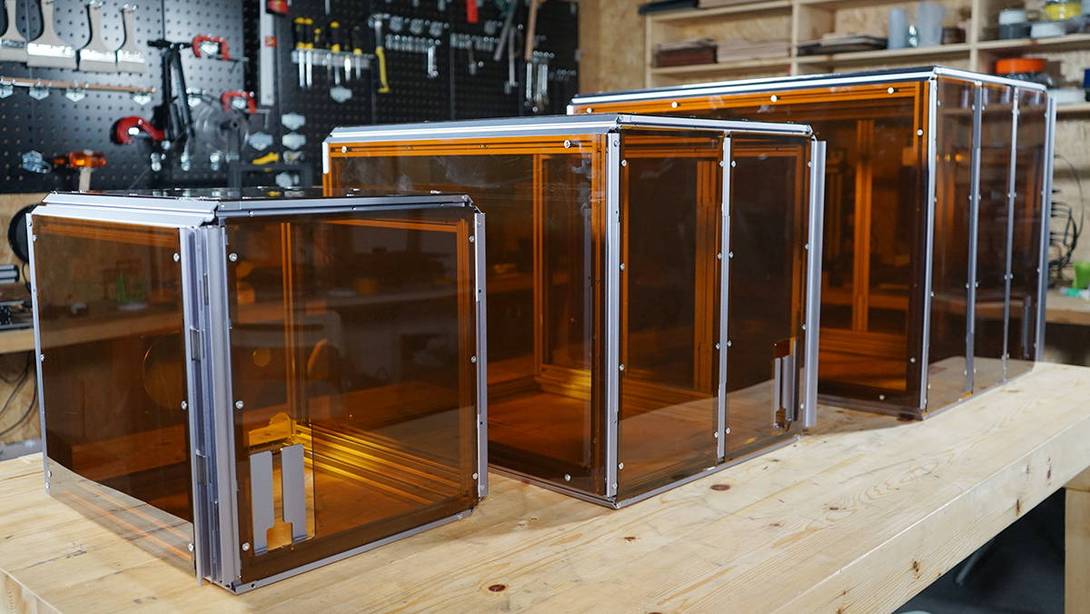

Along with all the new features coming with the Snapmaker 2.0 modular 3-in-1 3D printers, we are also developing new enclosures for A150, A250, and A350, which are currently close to the end of the design process. The following pictures show the early samples that we have assembled in early September. We proved out most of the features. For the doors, we have further modified the design to increase their firmness. The new samples with updated design just arrived today. We will finalize the enclosures’ design in early October.

We have carefully analyzed the product design and reviewed customer feedback of the enclosure for Snapmaker Original model when designing the new enclosures. These enclosures are not only safer, more solid, but also easier to assemble, designed to be compatible with future add-ons and expansions.

All the rails used in the enclosures are part of the Snapmaker 2.0 modular system.They can be used to construct expanded models with the modular 3D printers. Using folding door design, the enclosure will take up much less space when opening the doors and reduce the risk of a crash.

The enclosures will be available for preorder in your BackerKit Survey if you have backed or pre-ordered the Snapmaker 2.0. You will receive the survey via email about one month before your Snapmaker 2.0 is shipped.

The pilot production #2 has proved out the manufacturing process

The pilot production #1 (initial trial run) is finished. Now we are in the most critical moment in pilot production #2 (small scale). In this period, we focus on the assembly line and the more comprehensive whole machine testing using more test units. To ensure the production capacity and quality, we have cooperated with a reputable assembly plant. The assembly instructions were created and the workers were trained. The modules of 90 units have been manufactured by the assembly line to prove out the manufacturing process. On 18th September, all these modules were transferred to our office for more extensive testing.

We need more time to fix the problems arose in whole machine testing

We completed Module Testing in early September, though some hiccups caused a delay of a week or so. Things were going just fine. However, during Whole Machine Testing, we must overcome even more unexpected challenges that take us a lot of time to get things done. There are two significant problems currently: the problems related to Linear Modules' motion, and the problems associated with the camera's wireless signal inside the Laser Module.

We have been conducting extra tests on the solutions, and we are racing against time to validate them. We won’t move on to the next step, mass production, until the problems exposed in the pilot production process are solved. We are sorry that we can’t give an updated delivery schedule. We can evaluate and update the delivery schedule as soon as we complete the test data analysis.

Though there are hiccups during the production process, we take them seriously, and we believe that we will resolve them in the end!

Much love,

The Snapmaker Team