Get Inspired: 4 Stunning Multicolor 3D Prints (and Their Settings)

The magic of watching a 3D print emerge from a blank build plate is undeniable. But for many, that magic exists in a world of grey plastic. To truly bring creations to life, makers often spend hours painting and finishing their models. What if you could skip all that and get a vibrant, detailed object straight off the printer?

Welcome to the multicolor revolution. This exciting technology lets you create stunning, finished-looking objects directly on the print bed. This article will showcase four incredible multicolor 3d prints, from fast benchmarks to functional multi-material models, and share the key settings to show how they were made.

A Showcase of Inspiring Multicolor 3D Prints

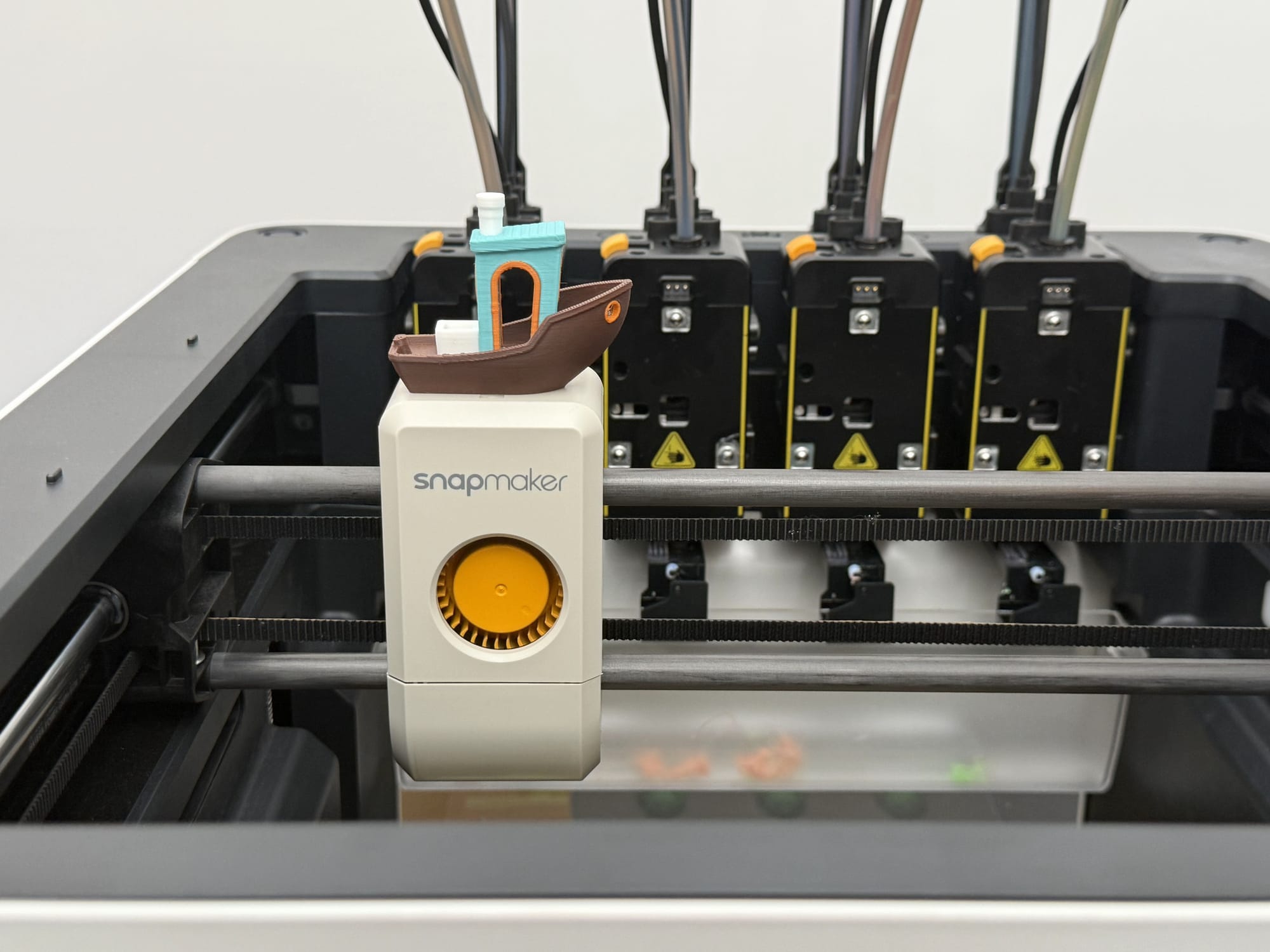

The High-Speed Benchmark: A 4-Color Benchy

The 3D Benchy is the universal "hello, world" of 3D printing, but this version is a true statement piece. It’s a high-quality, four-color model with sharp, clean lines between a dark brown hull, a light green cabin, and a white and light blue smokestack. This project is a perfect demonstration of how modern multicolor printing can produce a flawless, vibrant result with both speed and precision in just over two hours.

Watch a time-lapse of the 4-color Benchy being printed.

Key Print Settings:

- Print Time: 2h 17m

- Material: Snapmaker SnapSpeed PLA (36.07g)

- Layer Height: 0.2 mm

- Nozzle: 0.4 mm stainless steel

- Speed & Acceleration: 10000 mm/s², Infill 270 mm/s, Walls 200 mm/s

- Shell & Infill: 5 Bottom / 3 Top / 2 Walls, 15% Grid Infill

- Model Credit: Daniel Norée (Creative Tools)

The Detailed Masterpiece: A 4-Color Tiger Cub

This beautiful tiger cub demonstrates the reliability and fine detail possible in a long, large-scale print. Creating such a piece without multicolor technology would require tedious, difficult hand-painting to get the details right. Instead, this project flawlessly manages multiple spools of filament over a 20-hour print to create the orange body, yellow stripes, and white accents for the face and paws. After a quick cleanup of support structures, the final model is a solid, statue-like piece ready for display.

A close-up look at the finished 4-color tiger cub.

Key Print Settings:

- Print Time: 20h 20m

- Material: Snapmaker SnapSpeed PLA (516.39g)

- Layer Height: 0.2 mm

- Nozzle: 0.4 mm hardened steel

- Infill: 8%, Adaptive Cubic

- Model Credit: 3DMDesign on MakerWorld / Matmire_Makes on Cults3D

Beyond Color: Multi-Material Butterflies

This project is a look into the future of desktop manufacturing. It's not just multicolor; it's multi-material. The magic is revealed when the printed butterfly is picked up and its delicate, almost lace-like wings flex. This is achieved by combining rigid PETG for the body with flexible, rubber-like TPU for the wings in a single, one-hour print. This technique opens up a new world of functional objects, perfect for creating unique jewelry or charming home decor.

This charming butterfly was created with multi-material 3D printing, combining rigid and flexible filaments in a single print for beautiful home decor.

Key Print Settings:

- Print Time: 1h 7m

- Material: PETG Black + TPU White (95A), Red (95-HF), Blossom Red (95A)

- Layer Height: 0.2 mm

- Nozzle: 0.4 mm stainless steel

- Infill: Outline 15% Grid, Wings 35-40% Line

- Model Credit: @variableseams

Functional Fun & Less Waste: The Articulated Cyber Crab

This project is about creating complex, functional objects with zero assembly. The Cyber Crab comes right off the print bed with its legs and claws moving freely. This "print-in-place" capability is revolutionary for making toys, prototypes, and mechanical parts.

Crucially, this method is also incredibly efficient. In many multicolor systems, a lot of filament is wasted during color changes—this is the "purge waste" that's flushed out to prevent colors from mixing. The amount of waste depends on factors like how often colors are swapped and if you're changing from a dark to a light color (which requires more purging).

As shown with the Cyber Crab, a modern system can reduce this waste by up to 90%. By optimizing how and when colors are swapped, it uses significantly less purge material on each change. This means you're not just creating more beautiful and complex prints; you're doing it in a smarter, more sustainable, and more cost-effective way.

Watch a time-lapse of the articulated cyber crab being printed.

Key Print Settings:

- Print Time: 13h

- Material: Snapmaker SnapSpeed PLA (191.09g)

- Layer Height: 0.2 mm

- Nozzle: 0.4 mm Hardened Steel

- Infill: 5% Grid

- Model Credit: @flexifactory

How to Get Started with Multicolor Printing

Inspired by these projects? Getting started with multicolor printing is easier than you think. The process begins with powerful slicer software, like Snapmaker Orca. Here’s a general guide to the workflow:

- Prepare Your Model: You can start with any standard 3D model file, like an STL.

- Digitally Paint Your Model: You can use built-in tools to "paint" your model. The process is intuitive: you select a color that corresponds to a filament spool on your printer and apply it directly to the different faces of your 3D model. You repeat this for every color you want to use.

- Slice and Print: Once your model is colored, the software does the hard work. Snapmaker Orca uses engineer-tested profiles to automatically calculate all the tool changes and filament swaps needed for a perfect print. From there, you can use the Snapmaker App to send the file to your printer, monitor its progress, and even capture a timelapse of your vibrant creation coming to life.

Pro Tip: For users in professional settings who need to prepare extremely complex models or require industrial-level file repair, advanced software like Materialise Magics offers a powerful suite of tools for data and build preparation.

Technology Behind Multicolor 3D Prints

The impressive projects shown above are made possible by the latest generation of multi-filament 3D printers, exemplified by the Snapmaker U1. It leverages a sophisticated tool changer system to make multicolor and multi-material printing faster, more reliable, and more efficient. Each project highlights one of its key strengths:

- Speed & Precision: The lightning-fast yet clean print of the Benchy is a result of the U1's high-speed capabilities combined with its stable, rigid construction.

- Reliability: Printing the detailed, 20-hour Tiger Cub without issue is a testament to the U1's advanced multi-filament system, which handles complex color changes automatically.

- Multi-Material Versatility: The Butterflies project showcases the U1's ability to go beyond color, handling different material families like rigid PETG and flexible TPU in the same job to create functional parts.

- Efficiency: The Cyber Crab demonstrates the system's incredible efficiency. By optimizing the color-changing process, the U1 drastically reduces the filament waste common in other multicolor systems, saving both time and material.

Conclusion

From high-speed color and large-scale reliability to game-changing multi-material capabilities and functional parts that waste less material, these projects show the incredible potential of modern multicolor 3d printing. Technology is pushing the boundaries of what's possible on a desktop, turning creative ideas into finished products faster and more beautifully than ever before.