Are the Odors Released During 3D Printing Toxic?

As 3D printing becomes popular in homes and workplaces, many users are curious—and sometimes worried—about the odors it emits. While that distinct smell may seem harmless, one naturally wonders if the fumes pose any health risk. Are the odors toxic, or are they just an unpleasant byproduct of the process? This blog will answer the question, “Is 3D printing toxic?” and will help explain the potential risks and the best practices for safe management, primarily when using FDM (Fused deposition modeling) 3D printers.

Why 3D Printing Gives Off Odors

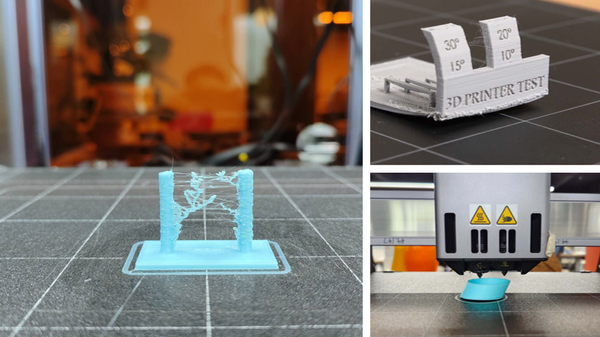

3D printing involves heating and depositing the thermoplastic filaments layer by layer to form a resultant object. These processes transform the materials, and the by-products either produce heat or fumes. You may wonder why 3D printing smells. The two prevailing factors behind the distinct smells emanating from these processes are Particle Matter (PM) and Volatile Organic Compounds (VOCs).

Types of Printed Materials

There are many different kinds of 3D printing filaments. The top three are ABS, PLA, and PETG. While the latter two types of filaments are safe, with little odor released into the environment during printing, others, like the ones mentioned above, ABS, have strong, nasty fumes. These odors could be given an even worse boost by using colorants or stabilization additives within the filaments.

Most consumer and industrial 3D printers use thermoplastic filaments like ABS, PLA, PETG, nylon, or composite materials like carbon fiber. Thermal decomposition at high temperatures applied to melt and extrude these plastics-there is usually a range of 180°C to 260°C-breaks down the polymers in the filament, which emit a complex mixture of VOCs and gases causing troublesome odors.

Even more environmentally friendly than the above is PLA, which does emit a slight smoke, and combined with other exotics such as nylon or carbon-fiber blends, which contain an element that will create pungent smells whenever heated, one of the primary smells being created in 3D printing from the decomposition of the materials.

Printing Environment

Printing in a closed, unventilated space ensures that fumes and odors in the print have nowhere to go; hence, they tend to accumulate in the air. Relatively mild odors might become more noticeable or hazardous as time proceeds.

Proper ventilation is required to minimize the concentration of fumes in the printing area. Printing in enclosed areas without ventilation exposes one to many VOCs and PM particles; hence, airflow during your 3D printing projects should be adequate.

Is the Smell Harmful?

Users have mixed opinions about the dangers of 3D printing fumes. While some consider them dangerous, others deem them harmless. The truth lies somewhere in between. Let’s examine the possible effects of 3D printing odors.

- Short-term Effects: After continuous exposure, some users experience headaches, eye irritation, or nausea.

- Long-term Concerns: Continued exposure to some VOCs poses chronic health effects, although more studies are still required.

- Material Differences: ABS is noted to emit more toxic particulates than PLA.

- Individual sensitivity: People have different sensitivities to these emissions.

While most home users will not risk their health from casual 3D printing, it's still worth being on the safe side—especially with heavy use or industrial applications. After all, you can never be too careful about your health.

Note: An odorless smell does not mean that there aren't any emissions. Carbon monoxide, for example, smells nothing but is highly poisonous.

How to Deal with Chemicals Released by 3D Printer

Managing fumes from 3D printers is critical, especially to preserve the safety and quality of a print environment. Here are some effective strategies for managing and minimizing risks from these fumes.

Ensure Ventilation With a 3D Printer Fume Hood

Use well-ventilated areas, or consider an enclosure with a 3D printer fume hood. Snapmaker offers the enclosure filtration solution. Snapmaker's 3D printers can be equipped with an enclosure and an air purifier, allowing users to 3D print in a room or office. The enclosed 3D printers smell a little.

Use Air Filtration

Utilize HEPA and Activated Carbon Filters—Include HEPA and activated carbon filters in your 3D printing room to filter particles and VOCs. Combine this with an air quality monitor for 3D printing so your place of 3D printing remains clean and free from emissions.

Choose Safer Materials

Whenever you can, use filaments that have less smelly odors—PLA.

Wear Protective Gear

Use a mask rated for satisfactory particulate capture when there is a need to do so.

Maintain Your Printer

Regular cleaning and maintenance of your printer can minimize the untimely emission of unnecessary compounds, such as volatile organic compounds.

Comparison with Resin (SLA) Printers

While this blog is about FDM print technologies, comparing them to resin-based SLA printers is interesting, too.

Emission types

● FDM: Heated plastic particles and VOCs are mainly emitted.

● SLA: Liquid resin emission gives off strong smells accompanied by its vapors.

Health concerns

● FDM: Though considered less toxic, risks mainly depend on the type of filament.

● SLA: Uncured resins are usually more toxic and cause skin irritation or allergic reactions.

Safety precautions

● FDM: Use ventilation and filtration.

● SLA: Safety precautions should be significantly greater, including gloves, ventilation, and taking proper care with uncured resins.

Odor intensity

● FDM: Too weak to cause a problem most of the time.

● SLA: Typically emits more robust, longer-lasting odors.

Post-processing

● FDM: Practically nothing is done to the final product, meaning they are exposed to very little.

● SLA: The solvent should be cleaned, and post-curing is needed to finish hardening the remaining uncured resin.

While both technologies have their place, FDM printing is generally considered safer for home use, especially when using low-emission filaments like PLA.

Final Thought

Odors resulting from the FDM 3D printing process are indeed disturbing. Yet proper precautions can limit the potential risks. As technology expands, we'll see more eco-friendly products and improved systems controlling emissions.