How to Cut MDF Board: Best Tools & Techniques

MDF, or medium-density fibreboard, is a versatile product that breaks down hardwood or softwood residuals into wood fibre. It is mainly used in woodworking, furniture building, and crafting. Its smooth surface and uniform density make it ideal for projects requiring a polished finish.

Cutting MDF boards correctly is essential for achieving clean, precise results in woodworking and crafting. So if you are looking for various techniques to cut the MDF board properly, this guide is for you.

How to Cut MDF Manually

If you don’t have power tools, you may manually cut MDF. Here’s how you can do it.

- Mark the cutting line sharply with a straight edge and a sharp pencil.

- With a hand saw, cut straight with a hand saw: a straight edge guide is clamped along the cutting line.

- Start the cut slowly to groove the surface.

- Use the full length of the saw, applying a smooth stroke while letting it work by itself more or less due to its weight.

- Cut slopes at least 45 degrees off the saw face to gain better control.

If you want to cut thin MDF boards without using power tools, utilize a utility knife.

- Next, the thin (3 mm or less) MDF material could be cut with a utility knife:

- Slice along the caulked cutting line several times and apply a steady and firm pressure.

- When there is a deep score, carefully snap it along the score line.

Manual cutting is most appropriate for smaller projects or budget-conscious users.

Power Tools for Cutting MDF Board: Speed and Efficiency

If you want to employ power tools for cutting MDF, use the following tools.

Jigsaw Blade – A jigsaw is ideal for cutting odd shapes.

- Attach a Blade: Use a 7-12 TPI blade for reduced tear-out. Opt for 12 TPI on jigsaws for precise, curved cuts.

- Score a Line: Score the cut line with a utility knife for better accuracy and sand the edges after cutting.

- Secure the Material: Clamp the MDF securely or use a sawhorse for larger boards to ensure safe, accurate cuts.

Note: Do not force your jigsaw blade through the board. High pressure on the blade will bend or snap the blade.

Router

- Use a Router Effectively: Score a cut line, use a carbide flute bit, and secure the MDF properly for bespoke edges and shapes.

- Consider Cost: Routers and additional bits can be expensive and may not be practical for occasional use.

- Opt for Professional Services: Save money and avoid mistakes by using specialist cut-to-size MDF services.

Circular Saw – Ideal for cutting straight edges, especially for long MDF panels

- Apply General Tips: Follow basic MDF cutting tips, including using a sawhorse for support.

- Ensure Precision: Unlike a jigsaw, a circular saw guarantees straight cuts with minimal effort.

- Manage Dust: Opt for a circular saw with a vacuum system to reduce dust production.

MDF produces fine dust that can be hazardous. Always:

- Wear a dust mask and safety goggles.

- Work in a well-ventilated area or use a vacuum attachment.

CNC Routing for Precision Cutting: The Professional Approach

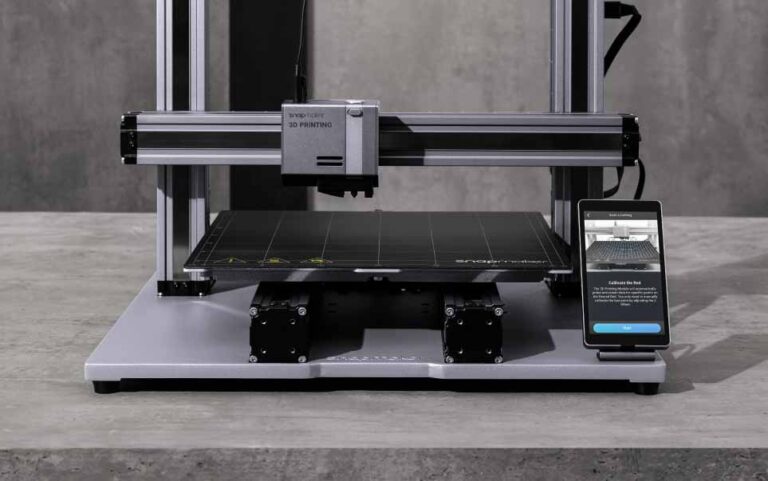

A CNC router is the gold standard for complex designs or high-precision work. It automates cutting and delivers flawless results. A CNC router operates by following a pre-programmed design file. It is the best way to cut MD as it cuts MDF boards with exceptional accuracy using adjustable spindle speeds and feed rates.

Tips for CNC Cutting MDF

- Use carbide-tipped bits for durability. A flat end mill (cutting diameter: 1.5 mm) is recommended.

- Set step down to 2.2 mm and feed rates around 500 mm/min to avoid burning.

- Keep spindle speeds around 18,000 RPM for clean edges.

Note: The data is tailored for the 50W CNC module and is for reference only.

Benefits

- Perfect for intricate patterns and large-scale projects.

- Provides consistency in cuts and a professional finish.

Preventing Common Cutting Issues

You may experience problems like burn marks or rough edges when cutting MDF. Here’s how you can prevent such problems.

Choosing the right bit is essential for achieving clean cuts. Upcut bits pull chips upward, improving cooling and reducing the risk of burning. Downcut bits, in contrast, push material downward, leaving a smoother top surface. For optimal results, consider using a compression cutter, which combines upcut and downcut flutes to prevent furring and ensure clean edges on both sides.

Running a CNC router at excessive speeds can create friction and heat, leading to burn marks on the wood. Lowering the RPM helps the bit cut smoothly, minimizing the risk of burning or furring along the edges.

Finishing and Sealing MDF Board

The easiest way to finish an MDF edge is to seal it. The sealer can be made from a mix of Primer paint, PVA, and water in a ratio of 10:5:1 or simply half PVA and a drop of water to make the mixture move smoother with the brush. Once one coat is dried, sand back with a 120-grit sanding block. Do another coat and sand again.

After applying the sealer, ensure the surface is completely dry before handling. If necessary, give the project a light sanding after the first coat of paint or sealer to eliminate any imperfections. This step will ensure the final finish is smooth and professional-looking.

By investing time in these finishing and sealing steps, your MDF project will look better and last longer, giving it a sleek, polished appearance that’s sure to impress.

Cutting MDF Board Like a Pro – Take Your Projects to the Next Level

This guide has provided a complete overview of how to cut MDF boards efficiently, from manual cutting techniques to advanced CNC routing. Whether you’re a beginner or a seasoned pro, understanding the tools and methods will help you achieve clean, precise cuts every time.For the ultimate cutting experience, consider investing in the Snapmaker Artisan + 200W CNC Module Bundle. This powerful tool delivers exceptional results for any MDF project.