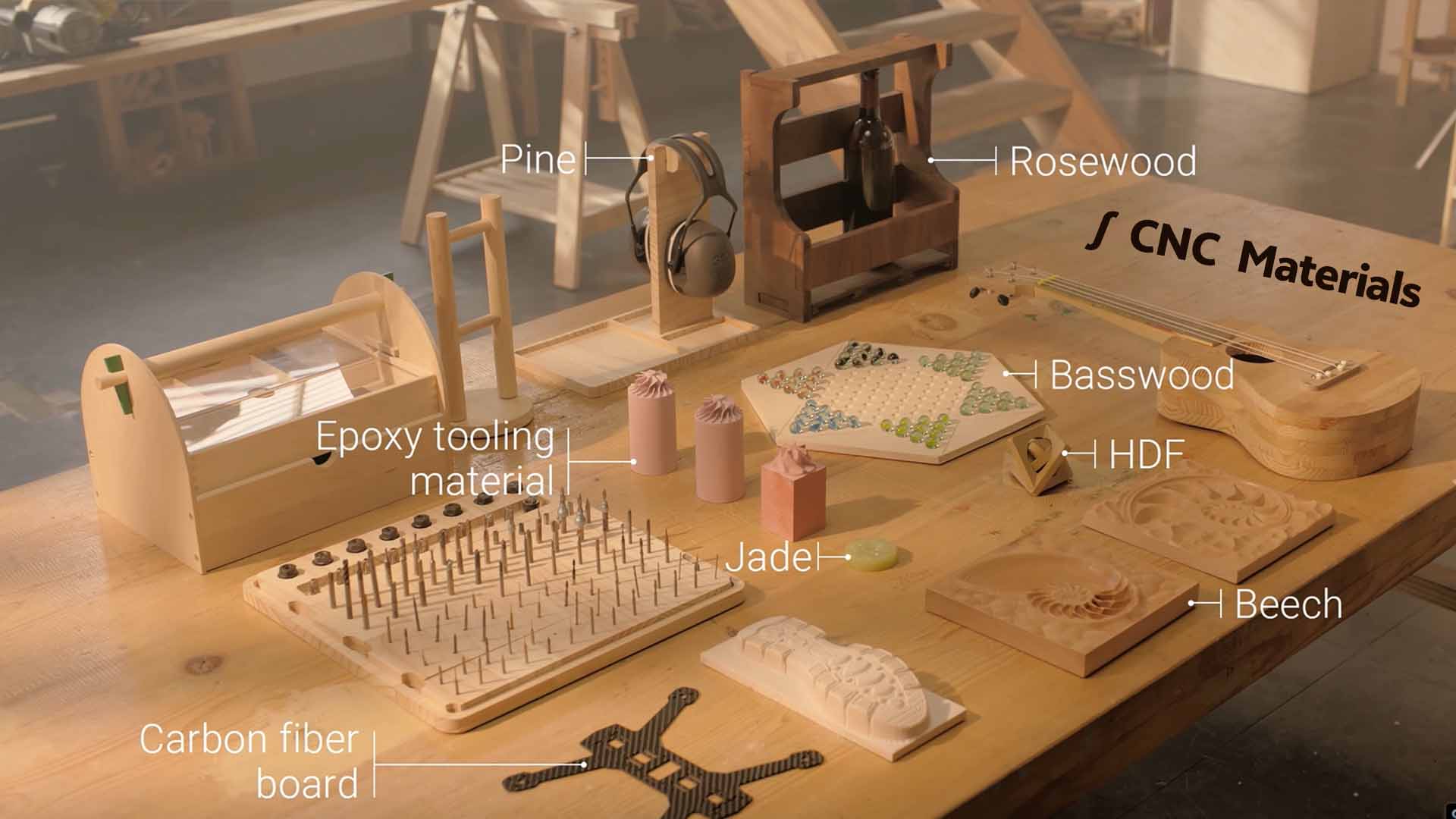

Guide to CNC Router Materials

Among many other differences, choosing the right material for your CNC project can make your product work properly, or it can be the source of great frustration. This comprehensive guide will go over the most commonly used CNC router (desktop) materials, their characteristics, and how to choose the right material for your application. Regardless of whether you’re a hobbyist or a professional, getting to grips with these basics will allow you to get better results in your CNC projects.

Common CNC Router Materials

CNC (Computer Numerical Control) routers can cut, carve and engrave an amazing range of materials. Each material has unique properties that make it suitable for specific types of projects. Here’s a breakdown of the top materials used in DIY CNC projects:

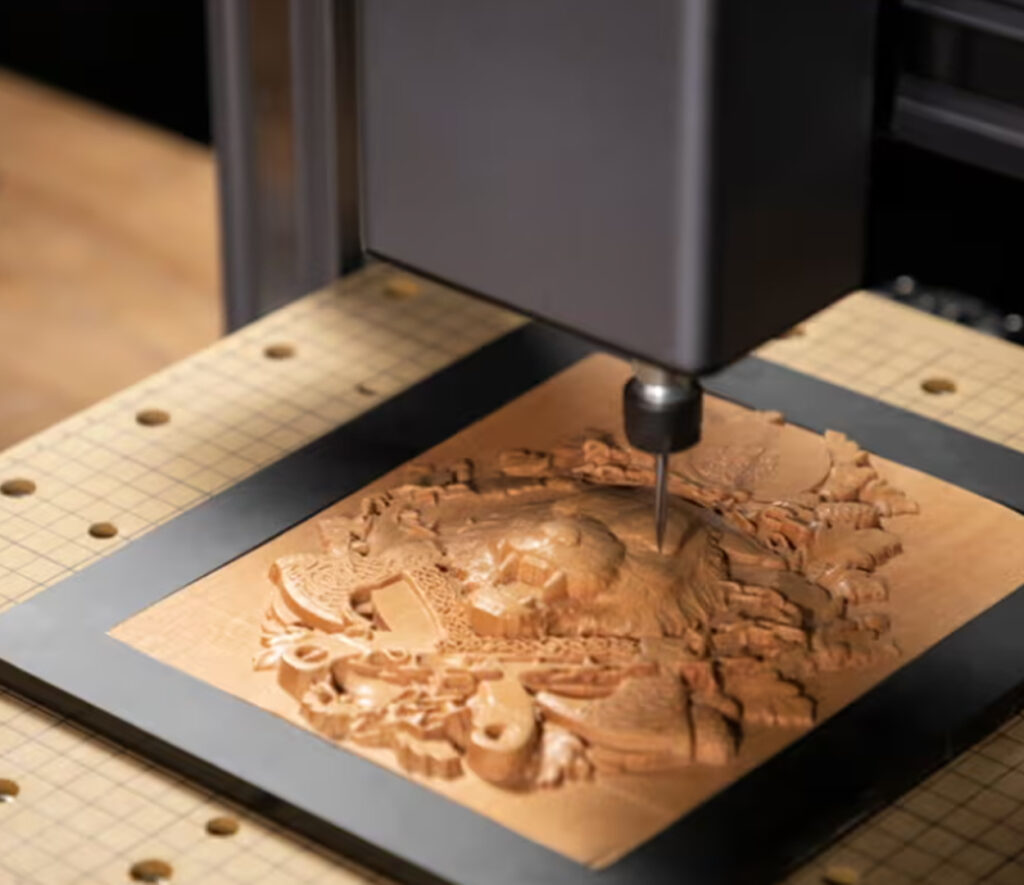

Wood & Wood-Based Materials

Wood is commonly used in projects such as signs, furniture, and decorative carvings. It is readily available and comes in many varieties, such as hardwood, softwood, and engineered wood. It is easy to carve, relatively inexpensive.

Common wood type: It covers oak, beech, cherry, walnut; pine, cedar, fir, and spruce; as well as medium or high density fiberboard (MDF, HDF), plywood, particle board, and veneer.

Properties:

- Easy to machine

- Various types to be had at all grades

- Cost-effective

- Excellent for beginners

- Biodegradable

Ideal Use Cases:

- Decorative signage

- Custom furniture

- Artistic relief carvings

- Architectural elements

Working Tips:

- Use softer woods such as pine to practice

- Modify bits accordingly (such as using a up-cut or down-cut spiral bits) to get a neat cutting and less tear-out, to avoid burning

- Plan cuts with grain direction in mind

- Keep feed rates correct to prevent from splitting

Recommended reading: How to Cut MDF Board

Plastic: Acrylic, PVC, HDPE

Materials such as acrylic, PVC, and other plastics are widespread choices for CNC projects due to their durability and availability. Acrylic is clear as glass, making it perfect for signs and displays, while PVC is great for making lightweight, durable parts.

Properties:

- Consistent material structure

- Come in weather-resistant options

- Available in different colours and transparencies

- Good dimensional stability

Ideal Use Cases:

- Indoor/outdoor signage

- Display cases

- Custom enclosures

- Precision components

Working Tips:

- Sufficient cooling (air or mist) to dissipate heat buildup

- Maintain constant feeding rates

- Adjust cutting speeds according to thickness

- Better carbide-tipped bits for longevity

Metal

A CNC router can cut and shape soft metals such as aluminum (1000-6000 series), brass, and red copper. Aluminum is more challenging than wood or plastic but is prized for its strength and precision, making it a great material for functional components or artistic creations.

Properties:

- High strength-to-weight ratio

- Excellent durability

- Premium finish potential

- Precise tolerances possible

Ideal Use Cases:

- Mechanical components

- Custom brackets

- Decorative panels

- Professional signage

Working Tips:

- Implementing proper cutting fluids

- Begin with conservative cutting speeds

- Correctly clamp workpieces

- Consider chip evacuation

Composite Materials: Carbon Fiber, Epoxy Tooling Board

Composite materials are made by combining two or more different materials that have different physical and chemical properties. Together, they create a material with different properties than the individual pieces.

Carbon Fiber: It is a tough and light material, popular in commercial aircraft, racing cars, and boats etc, which cuts differently for its fibrous nature and clogs up cutting tools more quickly, so demanding suitable tool grades, correct feed and speeds, and effective dust extraction, all of which could otherwise harm the tool, or more importantly the machinist!

Epoxy Tooling Board: This extremely rigid material is perfect for the manufacturing of molds, jigs and fixtures, it is machinable on standard CNC tooling though it does produce a great deal of dust this therefore requires efficient dust extraction to maintain a clean shop environment and to prevent the development of respiratory problems.

Natural Minerals: Jade

Jade is known for its toughness, beauty, and cultural significance. So it is perfect for jewelry and ornamental carvings.

If you want jade to be the project material, consider the potential for cracking and overheating issues. Pay attention to the bit type and CNC processing parameters.

You can always turn to official guidance. Snapmaker cares about your creating experience, and here are the Recommended parameters for 200W CNC, which have undergone official testing.

Factors Influencing CNC Material Capacities

The more you know about the properties of your material, the better choices you can make for your CNC project. These differences in performance are governed by certain attributes of the materials:

- Material Hardness: High-hardness materials are tougher to carve with and need higher horsepower levels and can hasten potential tool wear. Foam or plastic will carve more quickly, with less force, although likely not as precisely as a harder material like wood and jade.

- Material Thickness: This has an impact on the cutting parameters of the machine, e.g., feed rate, cutting depth, etc. Thicker materials will almost always need slower speeds and more passes to cut cleanly.

- Expansion and Warping: Some materials, such as wood, expand and contract under differing temperatures and humidity, causing the pieces to warp between seasons.

- Humidity: This can have an impact on the final appearance of your project, so do think about how your material will perform over time.

How to Choose Materials for Your CNC Projects

Choosing the right material isn’t just something you want to do; it’s a strategic decision based on your project’s objectives. Here are a few things to consider as you select your materials:

- Goals of the Project: Is it a decorative thing, or merely practical? Decorative items may need more easily carved materials: wood or foam, while functional ones may need something more long lasting: plastic or metal.

- CNC Router’s Capabilities: Not every CNC router can handle every material. If using a hobby-level CNC machine, make sure the material is within that machine’s capabilities. Some routers for instance have trouble with thicker metals, so you need a material that’s compatible with your machine.

- Cost and Availability: Material cost and availability are important factors for hobbyists. Wood ($2–$15/BD FT) and foam (15–30/FT) are relatively cheap and widely available, found locally at stores. On the other hand, metals and custom made plastics can be more expensive by a lot, and may need to be ordered from specialized suppliers with minimum purchase requirements.

- Testing and Experimentation: If it is your first time behind a CNC machine, don’t be afraid to try out different materials to get a better idea about their properties and how your CNC router works with each of them. The practical experience gained will establish a good basis for what works best for your efforts.

Safety Considerations While CNC Machining

Never forget to wear proper protective gear, including safety goggles, soundproof protections, hand gloves, etc. Anytime you deal with materials or with sharp instruments be absolutely cautious.

Safety also depends on proper machine setup and maintenance. Make sure to regularly check for any loose parts, keep the work area clear, and be familiar with emergency stop procedures. Also, be sure to work in a well-ventilated space and avoid wearing loose clothing that can get caught in the machine.

Final thoughts

Successful CNC routing starts with proper material selection and understanding. While this is a handy reference point, keep in mind that hands on experience with different materials will be your best teacher. Use it in simple materials and projects first and tackling more and more complex combinations as your ability improves.