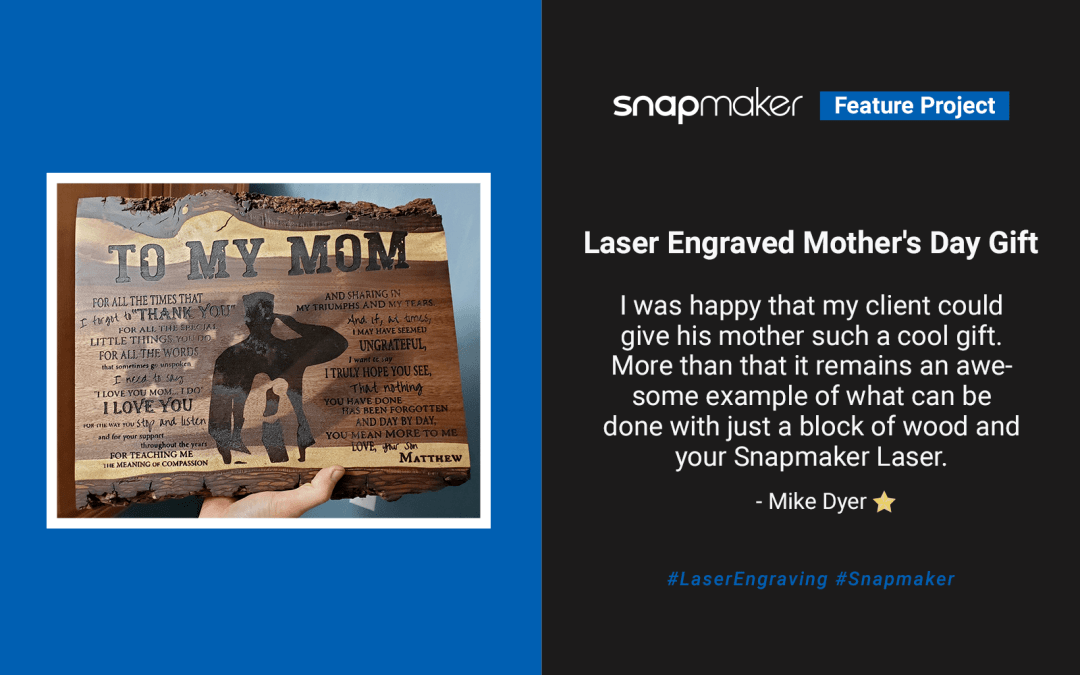

StarMaker | Custom-made Mother’s Day Gift with Laser Engraving

Project: Custom-made Mother’s Day Gift

Designed and created by: Mike Dyer

Mike’s platform: MD Creative Works

3D printer: Snapmaker 2.0 A350 with 1600mW Laser Module

Photo Edit Program: Photoshop; Gimp

Materials:

- Black Walnut (406 x 330 x 44 mm)

- Odie’s oil

Laser Engraving Settings:

- 100% Laser Power

- Work speeds most set to about 500

- Vector setting except the flag is grayscale

- Manually focus, go down until it lightly touches the surface, and then bring it back up 4mm on the Z-axis

Hello Fellow Makers,

I’m Mike. A customer came to me with a picture of a sign. They wanted to make it into a wooden plaque for Mother’s Day. The final product turned out beautiful, and I’m pretty proud of this work. All the work was realized by using the 1.6W Laser Module on my Snapmaker 2.0 – making it a remarkable example of the type of things you can create using this module.

So, here I will lay out the process that I took to create this using my Snapmaker machine.

First, I had to select a piece of material to do the laser engraving. I decided to cut off a chunk of black walnut out of an available piece. Once I had the canvas picked out for my project, I think I made a mock-up of what the project could look like for the customer’s approval and a guideline for myself to reference what I wanted the outcome to be. I did this by superimposing the original photo the customer sent onto the piece I had chosen; using a program such as Photoshop or Gimp would be the free option.

This project was a bit bigger than the bed of the machine, and some elements needed different settings. Therefore, I needed to set up multiple laser jobs to complete the project. Each element had to be separated and prepped before I could start the etching job. I used the large title from the original sign, but the smaller text was all retyped so that the result would be clear. I was also able to use the exact graphic of the soldier from the original picture and found an American flag graphic that was suitable online. The flag graphic was made slightly transparent and faded out on the edges so that there would be no hard lines. It is just the backdrop of the project, so I didn’t want anything that would particularly stand out.

Once all graphics were ready to go and I had my wood sanded to a smooth finish, I had to etch each element into the wood one at a time while moving the wood on the bed for the text on the sides. It is VERY important to note that you must adjust the origin before starting the next job when you move the thing you are lasering on. It would help if you made a reference spot for your work origin with a pencil before you begin and ensure that your project is perfectly parallel with the bed before starting the next steps. Any mistakes could mean resanding down the entire thing and starting over.

Each file was set up using Luban and ran one at a time. It’s best if you can run your files on a sample piece to ensure you have the desired effect before moving on to the actual project. A sample of the same material that you are using is best to see the result.

From the initial concept to the final result, I made the project look exactly like I had hoped, and I was pretty impressed with the result. It became a project I was very proud of, and I was happy that my client could give his mother such a fantastic gift. It remains an excellent example of what can be realized with just a block of wood and your Snapmaker.