What are the Pros and Cons of 3D Printing?

3D printing has tremendously gained a lot of attention because of the numerous benefits it offers. From building custom figurines to creating sculptures, homeowners can unleash their creativity to create several inventions of their liking. Having stated the various home uses of the 3D printing technology today, there are some negative sides of it, which should be borne in mind too. Since the topic of the guide is the pros and cons of 3D printing, below you will find more information about the benefits of this technology.

The Pros and Cons of 3D Printing

| Advantages | Disadvantages |

| Personalized Creations | Limited Build Size |

| Rapid Manufacturing | Limited Material Options |

| Ideal for Small Start-Ups | Complex Post-Processing |

| On-Demand Production | Copyright Issues |

| Reduced Waste | Slow Printing Speed |

Advantages: The Pros of 3D Printing

Now, let's discuss in detail the benefits of 3D printing, including customized creations, rapid manufacturing, etc.

Personalized Creations

The biggest advantage of 3D printing is the creation of customized items according to your ideas and preferences. Whether you want to give a customized gift to your loved ones or create a unique household decoration item, 3D printing does it all.

Rapid Manufacturing

With 3D printing, the lead times are fast, and you are able to manufacture the parts as well as prototypes quite fast. In fact, a 3D-printed part can be made in a single day, which makes it perfect for the development of new prototypes without taking into consideration the shipping time.

Ideal for Small Start-Ups

3D printing is also ideal for individuals looking to launch startups in the comfort of their homes. By rapidly producing custom products or prototypes at home in less than a day, you can save on expenses, including upfront costs.

On-Demand Production

Another excellent advantage of 3D printing is printing products exactly when required, eliminating the need for a huge storage space or inventories. This allows you to save time and space.

Reduced Waste

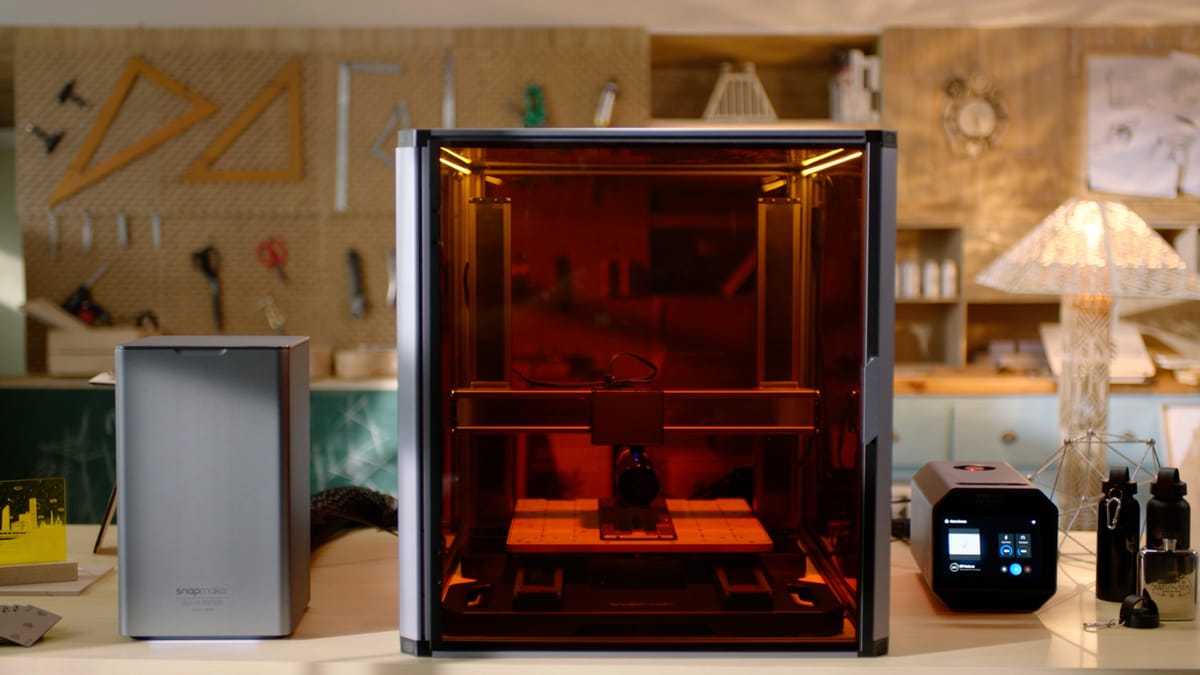

3D printing is eco-friendly as it uses materials like PLA, which is extracted from corn starch, making it non-toxic and renewable. It also reduces material waste by using the amount needed for each print. This is especially true for advanced multi-material printers like the Snapmaker U1. Its independent toolhead system eliminates the need to purge large amounts of filament when changing colors, cutting down on plastic waste significantly compared to traditional methods.

Also, items can be printed only when they are needed, eliminating the need for shipping from manufacturing plants. This in turn eliminates the energy costs associated with transportation.

Disadvantages: The Cons of 3D Printing

However, not everything is so great when it comes to 3D printing. There are also some disadvantages that should be taken into consideration. In this respect, let's take a look at some limitations of 3D printing that may arise when it comes to 3D printing and how to avoid them:

Limited Build Size

The biggest limitation of 3D printing is its inability to print large parts. Most home 3D printers have smaller build chambers, preventing huge prints. However, you can resolve this issue by printing multiple pieces and assembling them later, or you could use a large printer like the Snapmaker Artisan. With its massive 400mm x 400mm x 400mm build area, it allows you to print large parts in one go easily.

Limited Material Options

Another limitation of 3D printing is that it has limited material choices. This is because it supports some types of plastic or metals. Other types of materials are not yet supported by 3D printing. This, therefore, gives you limited material choices.

Complex Post-Processing

3D printed parts often need post-processing, like removing support structures, UV-light curing, polishing, sanding, or painting. This can be avoided by designing items that need no support structures or designing them in such a manner that they will not be too painful to remove. Additionally, you can sand, paint or polish your prints to make them look even more professional.

Copyright Issues

Another issue with 3D printing is that as it becomes more accessible, the risk of developing counterfeit products, illegal designs, and intellectual property infringement increases. Millions of freely available designs on the internet can be easily downloaded and copied without crediting the original owner. Therefore, it’s advised to be mindful of proper copyright practices before using 3D printing technology.

Slow Printing Speed

One of the limitations of the FDM 3D printers is that printing big parts with the use of these printers takes a long duration. The speed of printing depends heavily on the printer's extrusion system. For instance, direct drive extruders, which attach right on the print head, shorten the path from the feeder to the nozzle. This setup tends to be more reliable but makes the print head heavier and slows it down. On the other hand, Bowden-style extruders keep the extruder separate from the print head, sending the material through a long tube to the nozzle. This makes the print head lighter and speeds up the process. However, it's worth noting that this setup often sacrifices precision and increases the likelihood of printing errors.

Summary

3D printing has revolutionized home-based applications as users are now able to print designs of their choice. Although it has various advantages due to which one can design anything quickly and get prints as per order, there are disadvantages too, such as delaying the processing or being constrained by material choices. However, it is necessary to make a critical decision based on the pros and cons of 3D printing and then decide according to your needs and preferences.

Frequently Asked Questions (FAQ)

Q: Are 3D printer supplies expensive?

A: Basic 3D printer supplies for FDM 3D printing are relatively cheaper. The prices of 3D printer filaments are around $20 to $50 per kilogram and $60 to $120 for specialized engineering or support filaments.

Q: How do beginners start using 3D printers?

A: The simple process of 3D printing involves designing the 3D model by using CAD software. Then, it is converted to an STL file that the 3D printer recognizes. Next, they would prepare the 3D printer and build the item.